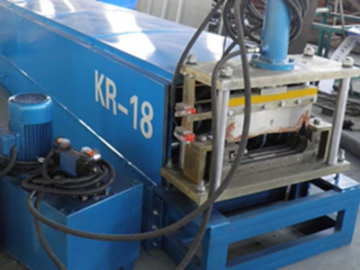

750 Roll Forming Machine

The 750 roll forming machine is used to construct the roofs of various industrial workshops, warehouses and other structures. Those roll-formed corrugated sheets are characterized by high wave crest, good mechanical strength, safe installation, as well as strong resistance to water, wind and rainstorm. Most importantly, this roofing sheet making machine provides a quality solution for roof leakage. It can work with a curving machine to produce curved roof panels.

The metal roofing machine is well-suited for medium and large-sized companies. It is commonly applied in various industrial and residential buildings, such as workshops, garages, hangars, gyms, exhibition halls, theaters, and so forth.

Features of the Roll Forming Machine

1. The colored steel roof forming machine uses automatic control software to realize efficient production management.

2. The automated control system features a highly-integrated network, which contributes to a greatly improved performance.

3. Our roof panel roll forming machine is easy to operate, repair, maintain and debug. Its roll forming dies are quickly and conveniently replaced.

4. A whole set of automatic lubrication system is provided. It can work on bearings, transmission gears, guide rails and other components when our machine is running.

Main Technical Parameters of the Roll Forming Machine

| Sheeting Thickness | 0.3-0.8mm |

| Max. Speed | 8m/min |

| Feeding Width | 1000mm |

| Effective Width | 750mm (Error: ±1) |

| Roof Depth | 35mm |

| Roll-forming Shaft | 13 rows |

| Thickness of Iron Plate | 14mm |

| Overall Dimension | 7500mm×1300mm×1000mm |

| Motor Power | 4kW |

| Roll Material | 45# steel, Hard Chrome Plating |

| Spindle Material | 45# steel, solid shaft, φ70mm diameter |

| Speed Reducer | 4# cycloidal speed reducer |

| Sprocket and Chain | 1.31 inch |