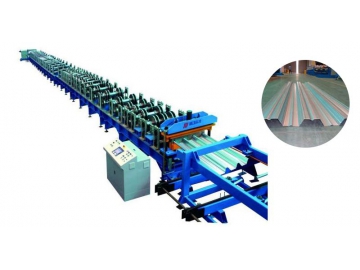

750 Metal Deck Roll Forming Machine

The 750 metal deck roll forming machine is used to produce simple-style steel floor decks with features of high wave steepness and good mechanical strength. Those steel decks can be firmly attached to concrete after the laying of spot-welded mesh is completed. When applied in high-rise buildings, this deck forming line helps to save a great number of steel plates and reduce the heavy loads on each floor. It also helps to reduce steel consumption and thereby save cost considerably.

Components of the Steel Deck Forming Machine:

1. An uncoiler,

2. A feedstock guiding table,

3. A roll former,

4. A puncher,

5. A cutting device,

6. A hydraulic power unit,

7. A computer control system,

8. And so forth.

Specifications of the 750 Metal Deck Roll Forming Machine

| Width of Feed Material | 1000mm |

| Motor Power | 18.5kW |

| Working Pressure | 10MPa |

| Frame Material | 360 steel |

| Roll-Forming Shaft | 22 rows |

| Machine Weight | 10T |

| Hydraulic Power | 4kW |

| Thickness of Iron Plate | 20mm |

| Material Thickness | 0.5-1.2mm |

| Dimension of the Floor Deck Machine | 11*1.5m |