FBH Combined Flow Closed Circuit Cooling Tower

The FBH combined flow closed circuit cooling tower provided by WANXIANG is a quality industrial closed circuit cooling machinery mainly suitable for water cooling of industrial apparatuses of high temperature(35°C to 50°C) and larger temperature difference(Δt=5-15°C). Meanwhile, we could provide you single-cell cooling tower, double-cell cooling tower, triple-cell cooling tower and double-module cooling tower.

Advantages

1. Increased working efficiency

2. Difficult to form scales

3. Easy maintenance

4. Direct-coupled fan without belt

5. Convenient modular combination

Applications

1. Temperature of liquids to be cooled: 35-60℃

2. Maximum temperature difference: 20℃, Optimum temperature difference: 6-10℃

3. Suitable wet bulb temperature for projects: ≥15℃

4. Average noise value: dB65-76

5. Suitable cooling rate for projects: more than 22L/s

6. Cooling capacity of single module: 250KW-2,910KW

7. This cooling tower is applicable to diversified industries, such as electric furnaces, smelting furnaces, crystallizers, solid melting furnaces, air compressors, rectifiers, industrial refrigeration units and the air conditioners for civil use, among others.

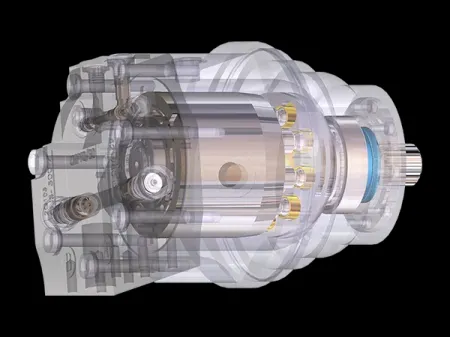

This combined flow closed circuit cooling tower could effectively cool the designated apparatus. The heat of flowing fluid inside the coils will be transferred by coils to the spay water which, being heated, becomes saturated vapor. The heat will be then exhausted by the draught fan and the water will be recollected by the catch basin and then be cycled again. The water will flow in the same direction as that of the fresh wind and be cooled down via PVC radiation fin in the process of circulation. Thanks to its sound cooling performance, this combined flow head rejection device has been widely used as the cooling system for industrial furnace.

Features of FBH Combined Flow Closed Circuit Cooling Tower

1. High efficiency. This spray cooling tower employs an excellent air supply system which significantly improves the air flow efficiency and helps the coils become more hydrophilic. Moreover, the cooling section could cool the spray effectively;

2. No deposits. Temperature of the spray water within this combined flow closed circuit cooling tower is controlled under the temperature that facilitates the scale formation. Moreover, the pipe is thoroughly wet, making it hard for the deposit to come into being;

3. Easy maintenance. This high-temperature cooling tower enjoys a large inside space which brings convenience to you during inspection and maintenance. Entering the tower through the access door, operator or inspector could go to check such key components as the coils and spray system directly.

Single Cell Closed Circuit Cooling Tower

Technical Specifications of Single Cell Closed Circuit Cooling Tower| Model | Flow 107.6-95°F (GPM) | Fan | Spew Pump | Inlet (out) (In) | Shipping Weight (lbs) | Operating Weight (lbs) | Dimensions | Basic Dimensions | |||||||

| Power (HP) | Airflow (CFM) | Power (HP) | Flow (GPM) | L (mm) | W (mm) | H (mm) | h1 (mm) | h2 (mm) | A (mm) | B (mm) | |||||

| 110 | 3 | 16941 | 1.5 | 158 | 4" | 3080 | 4785 | 1528 | 2250 | 3650 | 1935 | 1715 | 1780 | 2500 | |

| 132 | 4 | 23294 | 1.5 | 158 | 4" | 3212 | 4884 | 1528 | 2250 | 3650 | 1935 | 1715 | 1780 | 2500 | |

| 154 | 5.5 | 27529 | 1.5 | 158 | 4" | 3322 | 5060 | 1528 | 2250 | 3650 | 1935 | 1715 | 1780 | 2500 | |

| 136 | 4 | 23294 | 2 | 211 | 4" | 3828 | 5940 | 1850 | 2250 | 4150 | 2067 | 2083 | 2100 | 2500 | |

| 161 | 4 | 23294 | 2 | 211 | 4" | 4004 | 6160 | 1850 | 2250 | 4150 | 2067 | 2083 | 2100 | 2500 | |

| 194 | 5.5 | 27529 | 2 | 211 | 4" | 4235 | 6380 | 1850 | 2250 | 4150 | 2067 | 2083 | 2100 | 2500 | |

| 150 | 4 | 23294 | 2 | 211 | 4" | 4598 | 7238 | 1850 | 2610 | 4150 | 2067 | 2083 | 2100 | 2860 | |

| 176 | 5.5 | 33882 | 2 | 211 | 4" | 4906 | 7370 | 1850 | 2610 | 4150 | 2067 | 2083 | 2100 | 2860 | |

| 220 | 7.5 | 38117 | 2 | 211 | 4" | 5148 | 7678 | 1850 | 2610 | 4150 | 2067 | 2083 | 2100 | 2860 | |

| 231 | 5.5 | 38117 | 3 | 303 | 4" | 5786 | 8426 | 2330 | 2610 | 4150 | 2067 | 2083 | 2580 | 2860 | |

| 282 | 7.5 | 44470 | 3 | 303 | 4" | 6160 | 8624 | 2330 | 2610 | 4150 | 2067 | 2083 | 2580 | 2860 | |

| 311 | 10 | 50823 | 3 | 303 | 4" | 6468 | 8998 | 2330 | 2610 | 4150 | 2067 | 2083 | 2580 | 2860 | |

| 205 | 5.5 | 38117 | 3 | 303 | 4"(2) | 5170 | 7678 | 1850 | 2896 | 4150 | 2067 | 2083 | 2100 | 3150 | |

| 242 | 7.5 | 44470 | 3 | 303 | 4"(2) | 5390 | 7755 | 1850 | 2896 | 4150 | 2067 | 2083 | 2100 | 3150 | |

| 282 | 10 | 50823 | 3 | 303 | 4"(2) | 5940 | 8118 | 1850 | 2896 | 4150 | 2067 | 2083 | 2100 | 3150 | |

| 260 | 5.5 | 38117 | 3 | 303 | 4"(2) | 6512 | 9020 | 2330 | 2896 | 4150 | 2067 | 2083 | 2580 | 3150 | |

| 308 | 7.5 | 44470 | 3 | 303 | 4"(2) | 6776 | 9306 | 2330 | 2896 | 4150 | 2067 | 2083 | 2580 | 3150 | |

| 355 | 10 | 50823 | 3 | 303 | 4"(2) | 7480 | 9658 | 2330 | 2896 | 4150 | 2067 | 2083 | 2580 | 3150 | |

1. Model Code: FBH-062T (GS) 2. Reference conditions 3. This type H closed circuit cooling tower provided by WANXIANG is a quality cooling equipment mainly suitable for the water cooling of industrial apparatuses of high temperature(35°C to 50°C) and larger temperature difference(Δt=5-15°C). 4. This Type H closed circuit cooling tower has been certified to the CTI (Center Testing International) certificates. It is a combined closed circuit cooling tower which is constructed by some of the above single cell cooling towers whose technical specifications are applicable to the equipment. 5. Data in the above table are based on those of the closed circuit cooling tower whose surface air cooler is made of hot-dip galvanized steel. 6. For more single cell closed circuit cooling equipment, please resort to the WXSWL13.6 software which will offer you best selection suggestions. | |||||||||||||||

Dual Cell Closed Circuit Cooling Tower

Technical Specifications of Dual Cell Closed Circuit Cooling Tower| Model | Flow 107.6-95°F (GPM) | Fan | Spew Pump | Inlet (out) (In) | Shipping Weight (lbs) | Operating Weight (lbs) | Dimensions | Basic Dimensions | |||||||

| Power (HP) | Airflow (CFM) | Power (HP) | Flow (GPM) | L (mm) | W (mm) | H (mm) | h1 (mm) | h2 (mm) | A (mm) | B (mm) | |||||

| 227 | 3×2 | 33882 | 3 | 303 | 5" | 6160 | 9570 | 2976 | 2250 | 4150 | 2067 | 2083 | 3250 | 2500 | |

| 267 | 4×2 | 46588 | 3 | 303 | 5" | 6413 | 9768 | 2976 | 2250 | 4150 | 2067 | 2083 | 3250 | 2500 | |

| 311 | 5.5×2 | 55059 | 3 | 303 | 5" | 6655 | 10120 | 2976 | 2250 | 4150 | 2067 | 2083 | 3250 | 2500 | |

| 271 | 4×2 | 46588 | 4 | 435 | 5" | 7645 | 11880 | 3620 | 2250 | 4150 | 2067 | 2083 | 3870 | 2500 | |

| 322 | 4×2 | 46588 | 4 | 435 | 5" | 7986 | 12320 | 3620 | 2250 | 4150 | 2067 | 2083 | 3870 | 2500 | |

| 388 | 5.5×2 | 55059 | 4 | 435 | 5" | 8470 | 12760 | 3620 | 2250 | 4150 | 2067 | 2083 | 3870 | 2500 | |

| 286 | 4×2 | 46588 | 4 | 435 | 5" | 7106 | 11000 | 2976 | 2610 | 4150 | 2067 | 2083 | 3250 | 2860 | |

| 337 | 5.5×2 | 67765 | 4 | 435 | 5" | 7590 | 11330 | 2976 | 2610 | 4150 | 2067 | 2083 | 3250 | 2860 | |

| 403 | 7.5×2 | 76235 | 4 | 435 | 5" | 7986 | 11836 | 2976 | 2610 | 4150 | 2067 | 2083 | 3250 | 2860 | |

| 300 | 4×2 | 46588 | 4 | 435 | 5" | 9196 | 14476 | 3620 | 2610 | 4150 | 2067 | 2083 | 3870 | 2860 | |

| 374 | 5.5×2 | 67765 | 4 | 435 | 5" | 9801 | 14740 | 3620 | 2610 | 4150 | 2067 | 2083 | 3870 | 2860 | |

| 443 | 7.5×2 | 76235 | 4 | 435 | 5" | 10285 | 15356 | 3620 | 2610 | 4150 | 2067 | 2083 | 3870 | 2860 | |

| 462 | 5.5×2 | 76235 | 5.5 | 620 | 4"(2) | 11330 | 16852 | 4580 | 2610 | 4150 | 2067 | 2083 | 4830 | 2860 | |

| 564 | 7.5×2 | 88941 | 5.5 | 620 | 4"(2) | 12320 | 17248 | 4580 | 2610 | 4150 | 2067 | 2083 | 4830 | 2860 | |

| 623 | 10×2 | 101647 | 5.5 | 620 | 4"(2) | 12892 | 17996 | 4580 | 2610 | 4150 | 2067 | 2083 | 4830 | 2860 | |

| 410 | 5.5×2 | 76235 | 5.5 | 620 | 4"(2) | 10285 | 15356 | 3620 | 2896 | 4150 | 2067 | 2083 | 3870 | 3150 | |

| 484 | 7.5×2 | 88941 | 5.5 | 620 | 4"(2) | 10769 | 15510 | 3620 | 2896 | 4150 | 2067 | 2083 | 3870 | 3150 | |

| 564 | 10×2 | 101647 | 5.5 | 620 | 4"(2) | 11858 | 16236 | 3620 | 2896 | 4150 | 2067 | 2083 | 3870 | 3150 | |

| 593 | 7.5×2 | 93176 | 5.5 | 593 | 4"(2) | 14036 | 18810 | 3620 | 2896 | 4980 | 2551 | 2429 | 3870 | 3150 | |

| 663 | 10×2 | 101647 | 5.5 | 593 | 4"(2) | 15125 | 19536 | 3620 | 2896 | 4980 | 2551 | 2429 | 3870 | 3150 | |

1. Model Code: FBH-062T (GS) 2. Reference conditions 3. This dual cell cooling tower provided by WANXIANG is a quality cooling machinery mainly suitable for water cooling of industrial apparatuses of high temperature and larger temperature difference(Δt=5-20°C). 4. This closed circuit cooling tower has been certified to the CTI (Center Testing International) certificates. It is a dual cell closed circuit cooling equipment which is constructed by some of the above single cell cooling towers whose technical specifications are applicable to the equipment. 5. Data in the above table are based on those of the dual cell cooling tower whose surface air cooler is made of hot-dip galvanized steel. 6. For more information about available quality closed circuit cooling towers, please resort to the WXSWL13.6 software which will offer you best selection suggestions. | |||||||||||||||

Triple Cell Closed Circuit Cooling Tower

Technical Specifications of Triple Cell Closed Circuit Cooling Tower| Model | Flow 107.6-95°F (GPM) | Fan | Spew Pump | Inlet(out) (In) | Shipping Weight (lbs) | Operating Weight (lbs) | Dimensions | Basic Dimensions | |||||||

| Power (HP) | Airflow (CFM) | Power (HP) | Flow (GPM) | L (mm) | W (mm) | H (mm) | h1 (mm) | h2 (mm) | A (mm) | B (mm) | |||||

| 396 | 4×3 | 69882 | 4 | 435 | 5" | 9636 | 14652 | 4424 | 2250 | 4150 | 2067 | 2083 | 4680 | 2550 | |

| 462 | 5.5×3 | 82588 | 4 | 435 | 5" | 9988 | 15180 | 4424 | 2250 | 4150 | 2067 | 2083 | 4680 | 2550 | |

| 505 | 5.5×3 | 101647 | 5.5 | 620 | 4"(2) | 11748 | 17710 | 4424 | 2610 | 4150 | 2067 | 2083 | 4680 | 2860 | |

| 604 | 7.5×3 | 114353 | 5.5 | 620 | 4"(2) | 12232 | 18480 | 4424 | 2610 | 4150 | 2067 | 2083 | 4680 | 2860 | |

| 652 | 7.5×3 | 127059 | 5.5 | 580 | 5"(2) | 15004 | 21010 | 4424 | 2610 | 4980 | 2551 | 2429 | 4680 | 2860 | |

| 736 | 10×3 | 139765 | 5.5 | 580 | 5"(2) | 15730 | 21890 | 4424 | 2610 | 4980 | 2551 | 2429 | 4680 | 2860 | |

| 560 | 5.5×3 | 101647 | 5.5 | 620 | 5"(2) | 13673 | 21032 | 5390 | 2610 | 4150 | 2067 | 2083 | 5640 | 2860 | |

| 667 | 7.5×3 | 114353 | 5.5 | 620 | 5"(2) | 14278 | 21890 | 5390 | 2610 | 4150 | 2067 | 2083 | 5640 | 2860 | |

| 755 | 7.5×3 | 135529 | 7.5 | 791 | 5"(2) | 17182 | 24530 | 5390 | 2610 | 4980 | 2551 | 2429 | 5640 | 2860 | |

| 879 | 10×3 | 152471 | 7.5 | 791 | 5"(2) | 17908 | 25520 | 5390 | 2610 | 4980 | 2551 | 2429 | 5640 | 2860 | |

| 846 | 7.5×3 | 133412 | 7.5 | 857 | 5"(2) | 18480 | 25872 | 6830 | 2610 | 4150 | 2067 | 2083 | 7080 | 2860 | |

| 934 | 10×3 | 152471 | 7.5 | 857 | 5"(2) | 19338 | 26994 | 6830 | 2610 | 4150 | 2067 | 2083 | 7080 | 2860 | |

| 985 | 10×3 | 158824 | 10 | 1147 | 5"(2) | 19030 | 27830 | 6830 | 2610 | 4980 | 2551 | 2083 | 7080 | 2860 | |

| 1106 | 15×3 | 190588 | 10 | 1147 | 5"(2) | 20130 | 28820 | 6830 | 2610 | 4980 | 2551 | 2083 | 7080 | 2860 | |

| 725 | 7.5×3 | 133412 | 7.5 | 857 | 5"(2) | 16093 | 23100 | 5390 | 2896 | 4150 | 2067 | 2083 | 5640 | 3150 | |

| 850 | 10×3 | 152471 | 7.5 | 857 | 5"(2) | 17787 | 24200 | 5390 | 2896 | 4150 | 2067 | 2083 | 5640 | 3150 | |

| 934 | 10×3 | 152471 | 10 | 1147 | 5"(2) | 19360 | 26400 | 5390 | 2896 | 4980 | 2551 | 2429 | 5640 | 3150 | |

| 1037 | 10×3 | 158824 | 10 | 1147 | 5"(2) | 21054 | 27500 | 5390 | 2896 | 4980 | 2551 | 2429 | 5640 | 3150 | |

| 1168 | 10×3 | 158824 | 10 | 1147 | 6"(2) | 20240 | 27918 | 6830 | 2896 | 4980 | 2551 | 2083 | 7080 | 3150 | |

| 1311 | 10×3 | 190588 | 10 | 1147 | 6"(2) | 22440 | 29040 | 6830 | 2896 | 4980 | 2551 | 2083 | 7080 | 3150 | |

1. Model Code: FBH-3062T(GS) 2. Reference conditions 3.This triple-cell cooling tower provided by Wanxiang is a quality cooling machinery mainly suitable for water cooling of industrial apparatuses of high temperature and larger temperature difference(Δt=5-20°C). 4. This closed circuit cooling tower has been certified to the CTI (Center Testing International) certificates. It is a triple cell closed circuit cooling equipment which is constructed by some of the above single cell cooling towers whose technical specifications are applicable to the equipment. 5. Data in the above table are based on those of the triple cell cooling tower whose surface air cooler is made of hot-dip galvanized steel. 6. For more information about available quality multi-cell cooling towers, please resort to the WXSWL13.6 software which will offer you best selection suggestions. | |||||||||||||||

Closed Circuit Cooling Tower Arranged Back to Back

The closed circuit cooling tower arranged back to back is an independently designed cooling machinery provided by WANXIANG. Any derived types of this type H cooling tower can match another counterpart. As the following table shows, two such cooling towers could form double-module cooling equipment which is arranged back to back. The technical parameters of such multi-module cooling tower could be deducted by the following analogy.

| Model | Flow 107.6- 95°F (GPM) | Fan | Spew Pump | Inlet (out) (In) | Shipping Weight (lbs) | Operating Weight (lbs) | Dimensions | Basic Dimensions | |||||||

| Power (HP) | Airflow (CFM) | Power (HP) | Flow (GPM) | L (mm) | W (mm) | H (mm) | h1 (mm) | h2 (mm) | A (mm) | B (mm) | |||||

| Specifications of other types are omitted here | |||||||||||||||

| 747 | 7.5×4 | 169412 | 4×2 | 870 | 5"(2) | 8910 | 13400 | 3620 | 2610×2 | 4150 | 2067 | 2083 | 3870 | 5470 | |

| 886 | 10×4 | 186353 | 4×2 | 870 | 5"(2) | 9350 | 13960 | 3620 | 2610×2 | 4150 | 2067 | 2083 | 3870 | 5470 | |

| 967 | 7.5×4 | 177882 | 4×2 | 870 | 4"(4) | 9790 | 14100 | 3620 | 2896×2 | 4150 | 2067 | 2083 | 3870 | 6300 | |

| 1128 | 10×4 | 186353 | 4×2 | 870 | 4"(4) | 10120 | 14760 | 3620 | 2896×2 | 4150 | 2067 | 2083 | 3870 | 6300 | |

| 1304 | 7.5×6 | 254118 | 5.5×2 | 1240 | 5"(4) | 13640 | 19100 | 4424 | 2610× 2 | 4980 | 2551 | 2429 | 4680 | 5470 | |

| 1473 | 10×6 | 279529 | 5.5×2 | 1240 | 5"(4) | 14300 | 19900 | 4424 | 2610× 2 | 4980 | 2551 | 2429 | 4980 | 5470 | |

| 1121 | 7.5×6 | 254118 | 7.5×2 | 1714 | 5"(4) | 12430 | 19120 | 5390 | 2610× 2 | 4150 | 2067 | 2083 | 5640 | 5470 | |

| 1333 | 10×6 | 279529 | 7.5×2 | 1714 | 5"(4) | 12980 | 19900 | 5390 | 2610× 2 | 4150 | 2067 | 2083 | 5640 | 5470 | |

| Specifications of other types are omitted here | |||||||||||||||

This closed circuit cooling tower arranged back to back is widely used in large projects. Its unique multi-module structure is helpful for the pipe arrangement and ventilation of the cooling tower and makes it easier for users to build up the foundation. Correspondingly, the specifications of this closed circuit cooling tower arranged back to back are determined by those of its component cooling towers and also in accordance with piping and spray pump position (as is shown above).

Please be noted that there is a suffix "II" in this double-module tower’s model code. For example, the double-model tower of FBH-2062T is FBH-2062T-II. The types of two-box and three-box cooling towers are quite suitable for this double-module structure.