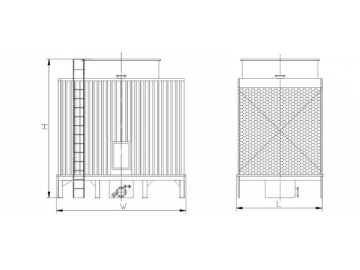

FKHL Crossflow Cooling Tower

Features of FKHL Crossflow Cooling Tower

Low Noise. This FKHL crossflow cooling tower is credited for its low noise and mixed flow design. As its coils are arranged at both sides, the open cooling equipment enjoys a larger space for air flow. And its fan throat, of a maximized size, could significantly expand the airflow area. The wide fan blades which, of lower rotating speed, are often used in the aviation and could effectively reduce the wind pressure and lower the noise.

Easy Maintenance. This combined flow closed circuit cooling tower enjoys a large inside space which brings convenience to you during inspection and maintenance. Entering the tower through the access door, operator or inspector could go to check such key components as the coils and spray system directly.

Application of FKHL Crossflow Cooling Tower

This low-noise counterflow cooling tower, of a compact structure, could be applicable to projects where the temperature of the materilas to be cooled is not so high (< 40°C) or the temperature difference is smaller (Δt=3-5°C). Now there are derived types oft this cooling tower available for customers, such as the civilian use crossflow cooling tower and the industrial crossflow cooling tower, and cross cooling towers for central air-conditioning system.

| Model | Flow 98.6- 89.6°C (GPM) | Fan | Inlet (In) | Outlet (In) | Shipping Weight (lbs) | Operating Weight (lbs) | Dimensions | Basic Dimensions | |||||||

| Power (HP) | Airflow Rate (CFM) | L (mm) | W (mm) | h1 (mm) | h2 (mm) | H (mm) | A (mm) | B (mm) | |||||||

| 267 | 3 | 28000 | 3"×2 | 5" | 3190 | 6270 | 1850 | 3792 | 2692 | / | 2992 | 2100 | 4050 | ||

| 311 | 4 | 35000 | 3"×2 | 5" | 3278 | 6380 | 1850 | 3792 | 2692 | / | 2992 | 2100 | 4050 | ||

| 355 | 4 | 34294 | 4"×2 | 6" | 3652 | 8338 | 2250 | 3792 | 2692 | / | 2992 | 2500 | 4050 | ||

| 436 | 5.5 | 49000 | 4"×2 | 6" | 3762 | 8470 | 2250 | 3792 | 2692 | / | 2992 | 2500 | 4050 | ||

| 388 | 4 | 37412 | 4"×2 | 6" | 4510 | 9196 | 2250 | 3792 | 3192 | / | 3492 | 2500 | 4050 | ||

| 469 | 5.5 | 48941 | 4"×2 | 6" | 4730 | 9416 | 2250 | 3792 | 3192 | / | 3492 | 2500 | 4050 | ||

| 557 | 7.5 | 62588 | 4"×2 | 6" | 4796 | 9460 | 2250 | 3792 | 3192 | / | 3492 | 2500 | 4050 | ||

| 597 | 5.5 | 55882 | 5"×2 | 6" | 5192 | 11506 | 2476 | 4792 | 2692 | / | 2992 | 2500 | 5050 | ||

| 667 | 7.5 | 68824 | 5"×2 | 6" | 5390 | 11660 | 2476 | 4792 | 2692 | / | 2992 | 2500 | 4050 | ||

| 637 | 5.5 | 61176 | 5"×2 | 6" | 5676 | 11968 | 2476 | 4792 | 3192 | / | 3492 | 2730 | 5050 | ||

| 766 | 7.5 | 78824 | 5"×2 | 6" | 5720 | 12100 | 2476 | 4792 | 3192 | / | 3492 | 2730 | 5050 | ||

| 828 | 10 | 86471 | 5"×2 | 8" | 5896 | 12320 | 2476 | 4792 | 3192 | / | 3492 | 2730 | 5050 | ||

| 905 | 15 | 99412 | 5"×2 | 8" | 5940 | 12474 | 2476 | 4792 | 3192 | / | 3492 | 2730 | 5050 | ||

| 758 | 7.5 | 72941 | 5"×2 | 8" | 6160 | 13244 | 2690 | 4792 | 3192 | / | 3492 | 2950 | 5050 | ||

| 824 | 10 | 85882 | 5"×2 | 8" | 6226 | 13530 | 2690 | 4792 | 3192 | / | 3492 | 2950 | 5050 | ||

| 934 | 15 | 97471 | 5"×2 | 8" | 6600 | 13706 | 2690 | 4792 | 3192 | / | 3492 | 2950 | 5050 | ||

| 1011 | 20 | 113529 | 5"×2 | 8" | 7106 | 14190 | 2690 | 4792 | 3192 | / | 3492 | 2950 | 5050 | ||

1. Model Code: FKHL-822D; 2. Reference conditions 3. Of a simple combination method, this crossflow cooling equipment is widely used in the industrial and civil areas. 4. Water in the catch basin could flow by itself as long as you enlarge the outlet aperture. 5. Combined by more than two cooling towers, the heat rejection device will be attached with interfaces for the connecting pipes. | |||||||||||||||

| Model | Flow 98.6- 89.6°C (GPM) | Fan | Inlet (In) | Outlet (In) | Shipping Weight (lbs) | Operating Weight (lbs) | Dimensions | Basic Dimensions | |||||||

| Power (HP) | Airflow Rate (CFM) | L (mm) | W (mm) | h1 (mm) | h2 (mm) | H (mm) | A (mm) | B (mm) | |||||||

| 927 | 10 | 89412 | 6"×2 | 8" | 7260 | 15356 | 2976 | 5220 | 3192 | / | 3492 | 3230 | 5470 | ||

| 956 | 10 | 99765 | 6"×2 | 8" | 7436 | 15818 | 2976 | 5220 | 3192 | / | 3492 | 3230 | 5470 | ||

| 1044 | 15 | 108941 | 6"×2 | 10" | 7766 | 16302 | 2976 | 5220 | 3192 | / | 3492 | 3230 | 5470 | ||

| 1147 | 20 | 126471 | 6"×2 | 10" | 8250 | 16786 | 2976 | 5220 | 3192 | / | 3492 | 3230 | 5470 | ||

| 1117 | 15 | 107059 | 6"×2 | 10" | 8646 | 18876 | 2976 | 5220 | 2551 | 1783 | 4634 | 3230 | 5470 | ||

| 1282 | 20 | 133529 | 6"×2 | 10" | 9130 | 19360 | 2976 | 5220 | 2551 | 1783 | 4634 | 3230 | 5470 | ||

| 1363 | 25 | 142353 | 6"×2 | 10" | 9196 | 19470 | 2976 | 5220 | 2551 | 1783 | 4634 | 3230 | 5470 | ||

| 1487 | 30 | 167059 | 6"×2 | 10" | 9592 | 19844 | 2976 | 5220 | 2551 | 1783 | 4634 | 3230 | 5470 | ||

| 1322 | 25 | 137647 | 6"×2 | 10" | 9680 | 20240 | 3620 | 5220 | 3192 | / | 3492 | 3870 | 5470 | ||

| 1429 | 30 | 148824 | 6"×2 | 10" | 10076 | 20724 | 3620 | 5220 | 3192 | / | 3492 | 3870 | 5470 | ||

| 1520 | 25 | 145882 | 6"×4 | 12" | 10538 | 23012 | 3620 | 5220 | 2551 | 1783 | 4634 | 3870 | 5470 | ||

| 1656 | 30 | 172353 | 6"×4 | 12" | 10956 | 23430 | 3620 | 5220 | 2551 | 1783 | 4634 | 3870 | 5470 | ||

| 1886 | 41 | 208824 | 6"×4 | 12" | 11330 | 23760 | 3620 | 5220 | 2551 | 2333 | 5184 | 3870 | 5470 | ||

| 2073 | 30 | 198176 | 6"×4 | 12" | 11990 | 24200 | 3620 | 6830 | 2551 | 1783 | 4634 | 3870 | 7100 | ||

| 2399 | 41 | 250882 | 6"×4 | 12" | 12276 | 24640 | 3620 | 6830 | 2551 | 1783 | 4634 | 3870 | 7100 | ||

| 2978 | 50 | 330529 | 6"×4 | 12" | 12540 | 25080 | 3620 | 6830 | 2551 | 2333 | 5184 | 3870 | 7100 | ||

| 2604 | 30 | 250588 | 6"×4 | 12" | 13310 | 26400 | 4250 | 6830 | 2551 | 1783 | 4634 | 4500 | 7100 | ||

| 2949 | 41 | 307412 | 6"×4 | 12" | 13860 | 26906 | 4250 | 6830 | 2551 | 1783 | 4634 | 4500 | 7100 | ||

| 3319 | 61 | 370000 | 6"×4 | 12" | 14256 | 27500 | 4250 | 6830 | 2551 | 2333 | 5184 | 4500 | 7100 | ||

1. Model Code: FKHL-822D; 2. Reference conditions 3. Water in the catch basin could flow by itself as long as you enlarge the outlet aperture. 4. Combined by more than two cooling towers, the equipment will be attached with interfaces for the connecting pipes. | |||||||||||||||

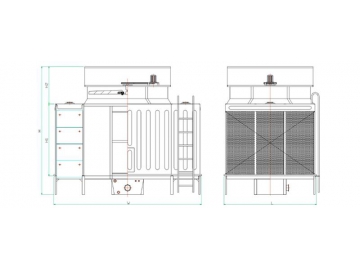

Multi module combination form

This multi-module combined cooling tower enjoys rich flexible combination methods which are determined by its specific working condition. Its dimensions data and pipes number are determined by the cooling towers constructing the equipment (just as the figure shows). And those of other counterparts could be deducted by this analogy.

| Model | Flow 98.6- 89.6°C (GPM) | Fan | Inlet (In) | Outlet (In) | Shipping Weight (lbs) | Operating Weight (lbs) | Dimensions | Basic Dimensions | |||||||

| Power (HP) | Airflow Rate (CFM) | L (mm) | W (mm) | h1 (mm) | h2 (mm) | H (mm) | A (mm) | B (mm) | |||||||

| Specifications of the multi-module combined cooling towers, taking those of the 852 type as an example | |||||||||||||||

| 2088 | 15 ×2 | 217 882 | 6" ×4 | 10" ×2 | 15532 | 32604 | 5952 | 5220 | 3192 | / | 3492 | 6200 | 5470 | ||

| 3132 | 15 ×3 | 326 824 | 6" ×6 | 10" ×3 | 23298 | 48906 | 8928 | 5220 | 3192 | / | 3492 | 9180 | 5470 | ||

| 4176 | 15 ×4 | 435 765 | 6" ×8 | 10" ×4 | 31064 | 48906 | 11904 | 5220 | 3192 | / | 3492 | 12240 | 5470 | ||

| Specifications of other cooling towers are omitted here | |||||||||||||||

| 1. Model Code: FKHL-822D; F: exhaust type; K: open type; 2: module number H: The spray water and wind are perpendicular; 822: machine code; D: noise grade. 2. Combined by more than two cooling towers, the combined crossflow cooling equipment will be attached with interfaces for the connecting pipes. | |||||||||||||||