FBN Counterflow Cooling Tower

Excellent Cooling Performance of FBN Counterflow Cooling Tower

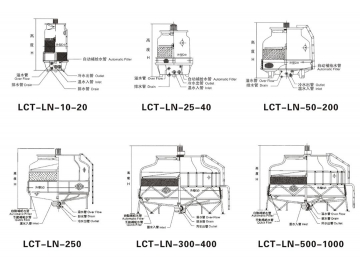

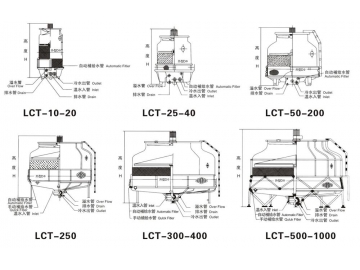

This FBN counterflow cooling tower is a reliable cooling apparatus which takes in wind from the bottom of the tower. The incoming air flows in counter direction with the water spray, and then turns into saturated vapors. The heat of the vapor will be exhausted by the wind fans on the top part and the water will be recollected by the catch basin and recycled again. With no cooling fillers inside the tower, this highly energy-efficient cooling tower is equipped with coils which enjoy expanded unit radiating areas.

Available Accessories for FBN Counterflow Cooling Tower

To some smaller cooling projects, we could provide you an integrated counterflow cooling apparatus which is combined by the cooling tower, circulation pump system and controlling system. Moreover, the small size cooling tower whose minimum refrigeration capacity is 6t/h is available for customers who have such needs now.

Main Characteristics of FBN Counterflow Cooling Tower

1. Compact structure for minimum space occupation

2. Smaller size of the product can be designed.

3. Air inlet design provides a fully sealed cell and an improved thermal insulation property within the tower.

Product Application of FBN Counterflow Cooling Tower

This counterflow shower cooling tower, of a compact structure, could be used in projects where the temperature of the materials to be cooled is not so high((< 40°C) or the temperature difference is smaller(Δt=3-5°C).

1. Temperature of liquids to be cooled: 25-40℃

2. Maximum temperature difference: 8℃, Optimum temperature difference: 3-5℃

3. Suitable wet bulb temperature for projects: ≥5℃

4. Average noise value: dB59-72

5. Suitable cooling rate for projects: more than 3L/s

6. Cooling capacity of single module: 58KW-1,150KW

7. The counterflow cooling tower is ideal for those projects which have requirements for low amount of cooling water, low water temperature, low temperature difference and low wet bulb temperature. For instance, it can be applied in medium-frequency power supplies, small electric furnaces and the air conditioners for civil use.

| Model | Flow 98.6-89.6°F (GPM) | Fan | Spew Pump | Inlet(out) (In) | Shipping Weight (lbs) | Operating Weight (lbs) | Dimensions | Basic Dimensions | |||||||

| Power (HP) | Airflow (CFM) | Power (HP) | Flow (GPM) | L (mm) | W (mm) | H (mm) | h1 (mm) | h2 (mm) | A (mm) | B (mm) | |||||

| 88 | 2 | 14824 | 0.75 | 84 | 2" | 2299 | 3894 | 1528 | 1448 | 2650 | 1081 | 1569 | 1780 | 1700 | |

| 99 | 3 | 19059 | 0.75 | 84 | 2" | 2563 | 4202 | 1528 | 1448 | 2650 | 1081 | 1569 | 1780 | 1700 | |

| 115 | 3 | 19059 | 1 | 103 | 2.5" | 2882 | 4532 | 1528 | 1448 | 2940 | 1081 | 1859 | 1780 | 1700 | |

| 126 | 4 | 23294 | 1 | 103 | 2.5" | 3146 | 4840 | 1528 | 1448 | 3220 | 1081 | 2139 | 1780 | 1700 | |

| 154 | 4 | 27529 | 1.5 | 165 | 4" | 3454 | 5852 | 1850 | 1770 | 2670 | 1096 | 1574 | 2100 | 2020 | |

| 170 | 5.5 | 33882 | 1.5 | 165 | 4" | 3872 | 6314 | 1850 | 1770 | 3300 | 1096 | 2204 | 2100 | 2020 | |

| 192 | 7.5 | 39176 | 2 | 237 | 4" | 4334 | 6820 | 1850 | 1770 | 3540 | 1096 | 2444 | 2100 | 2020 | |

| 209 | 7.5 | 39176 | 2 | 237 | 4" | 4730 | 7260 | 1850 | 1770 | 3970 | 1247 | 2723 | 2100 | 2020 | |

| 286 | 5.5 | 36000 | 3 | 303 | 3" (2) | 6798 | 9724 | 2330 | 2250 | 3550 | 1307 | 2243 | 2580 | 2500 | |

| 319 | 7.5 | 44471 | 3 | 303 | 3" (2) | 7546 | 10516 | 2330 | 2250 | 3550 | 1307 | 2243 | 2580 | 2500 | |

| 348 | 7.5 | 44471 | 3 | 303 | 4" (2) | 8426 | 11440 | 2330 | 2250 | 4050 | 1502 | 2548 | 2580 | 2500 | |

| 381 | 10 | 55059 | 3 | 303 | 4" (2) | 9152 | 12232 | 2330 | 2250 | 4480 | 1702 | 2778 | 2580 | 2500 | |

| 423 | 10 | 59294 | 4 | 435 | 4" (2) | 9174 | 15620 | 2976 | 2896 | 3720 | 1307 | 2413 | 3230 | 3150 | |

| 445 | 15 | 82588 | 4 | 435 | 4" (2) | 10285 | 16830 | 2976 | 2896 | 3720 | 1307 | 2413 | 3230 | 3150 | |

| 473 | 15 | 82588 | 4 | 435 | 4" (2) | 11550 | 18150 | 2976 | 2896 | 4150 | 1502 | 2648 | 3230 | 3150 | |

| 500 | 20 | 93176 | 5.5 | 620 | 4" (2) | 12628 | 19360 | 2976 | 2896 | 4500 | 1702 | 2798 | 3230 | 3150 | |

1. Model Code: FBH-564T(GS) 2. Reference conditions 3. This counterflow cooling equipment, of a compact structure, could be applicable to projects where the temperature of the fluid to be cooled is not so high (< 40°C) or the temperature difference is smaller (Δt=3-5°C). 5. Data in the above table are based on those of the counter flow cooling tower whose surface air cooler is made of hot-dip galvanized steel. 6. For more information about available quality counterflow cooling tower, please resort to the WXSWL13.6 software which will offer you best selection suggestions. | |||||||||||||||

| Model | Flow 98.6-89.6°F (GPM) | Fan | Spew Pump | Inlet(out) (In) | Shipping Weight (lbs) | Operating Weight (lbs) | Dimensions | Basic Dimensions | |||||||

| Power (HP) | Airflow (CFM) | Power (HP) | Flow (GPM) | L (mm) | W (mm) | H (mm) | h1 (mm) | h2 (mm) | A (mm) | B (mm) | |||||

| 176 | 2×2 | 29647 | 2 | 237 | 4" | 4576 | 7810 | 2976 | 1448 | 2650 | 1081 | 1569 | 3230 | 1700 | |

| 198 | 3×2 | 38118 | 2 | 237 | 4" | 5170 | 8426 | 2976 | 1448 | 2650 | 1081 | 1569 | 3230 | 1700 | |

| 234 | 3×2 | 38118 | 2 | 237 | 4" | 5786 | 9086 | 2976 | 1448 | 2940 | 1081 | 1859 | 3230 | 1700 | |

| 256 | 4×2 | 46588 | 2 | 237 | 5" | 6314 | 9680 | 2976 | 1448 | 3220 | 1081 | 2139 | 3230 | 1700 | |

| 308 | 4×2 | 55059 | 3 | 303 | 5" | 6875 | 11726 | 3620 | 1770 | 2670 | 1096 | 1574 | 3870 | 2020 | |

| 344 | 5.5×2 | 67765 | 3 | 303 | 5" | 7722 | 12628 | 3620 | 1770 | 3300 | 1096 | 2204 | 3870 | 2020 | |

| 388 | 7.5×2 | 82588 | 4 | 435 | 4" (2) | 8668 | 13618 | 3620 | 1770 | 3540 | 1096 | 2444 | 3870 | 2020 | |

| 418 | 7.5×2 | 82588 | 4 | 435 | 4" (2) | 9482 | 14520 | 3620 | 1770 | 3970 | 1247 | 2723 | 3870 | 2020 | |

| 571 | 5.5×2 | 72000 | 5.5 | 620 | 4" (2) | 12606 | 17864 | 4580 | 2250 | 3720 | 1307 | 2413 | 4830 | 2500 | |

| 637 | 7.5×2 | 88941 | 5.5 | 620 | 4" (2) | 13992 | 19338 | 4580 | 2250 | 3720 | 1307 | 2413 | 4830 | 2500 | |

| 696 | 7.5×2 | 88941 | 7.5 | 857 | 5" (2) | 15620 | 21032 | 4580 | 2250 | 4150 | 1502 | 2648 | 4830 | 2500 | |

| 762 | 10×2 | 110118 | 7.5 | 857 | 5" (2) | 16940 | 22484 | 4580 | 2250 | 4500 | 1702 | 2798 | 4830 | 2500 | |

| 857 | 5.5×3 | 108000 | 7.5 | 857 | 5" (2) | 16500 | 28116 | 6830 | 2250 | 3720 | 1307 | 2413 | 7080 | 2500 | |

| 956 | 7.5×3 | 133412 | 7.5 | 857 | 5" (2) | 18513 | 30294 | 6830 | 2250 | 3720 | 1307 | 2413 | 7080 | 2500 | |

| 1044 | 7.5×3 | 133412 | 10 | 1154 | 6" (2) | 20790 | 32670 | 6830 | 2250 | 4150 | 1502 | 2648 | 7080 | 2500 | |

| 1143 | 10×3 | 165176 | 10 | 1154 | 6" (2) | 22748 | 34848 | 6830 | 2250 | 4500 | 1702 | 2798 | 7080 | 2500 | |

1. Model Code: FBN-2554T(GS) 2. Reference conditions 3. This counterflow cooling tower, of a compact structure, could be applicable to projects where the temperature of the fluid to be cooled is not so high (< 40°C) or the temperature difference is smaller (Δt=3-5°C). 5. Data in the above table is based on those of the cooling tower whose surface air cooler is made of hot-dip galvanized steel. 6. For more available quality apparatuses, please resort to the WXSWL13.6 software which will offer you best selection suggestions. | |||||||||||||||