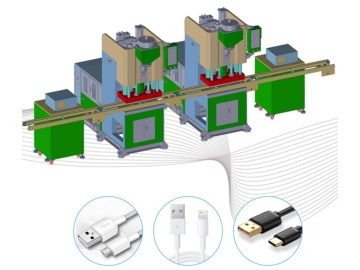

Automatic EVA Foam Injection Molding Machine (Single-Color)

The KM-E06L2/E08L2/10L2 automatic EVA foam injection molding machine utilizes a touchscreen to directly monitor machine movement and production. This injection molding machine is easy to operate, and widely used in the manufacturing of footwear, including slippers, tennis shoes, sandals, mid-soles, and other shoe accessories. In addition, the EVA injection molding machine is also used to make EVA toy wheels and other small toys and components.

Notable Features1. Control System

The control system uses an industrial workstation computer with a Windows operating system with a touch screen that clearly displays the operation type. This monitor will display the screw turning speed, injection volume time, injection temperature, mold temperature, movement time, and productivity of the production line. The control system is both easy to learn and operate.

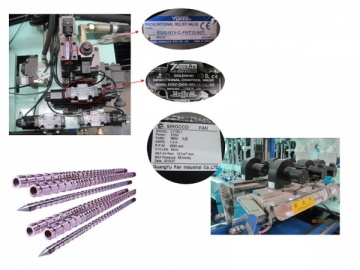

2. Injection System

The measuring mechanism utilizes potentiometer detection and coordinates with PLC control operation in order to control the material quantity. A linear track guide also allows for a quick movement and precise positioning.

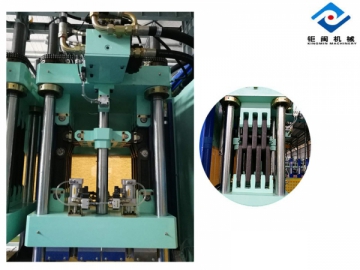

3. Mold Clamping System

Act by toggle mechanism, it opens the mould rapidly. The two-step speedy mould opening/closing mechanism with detecting device of fully mould closing. Lowing operation height, increased mould opening stroke, can apply to various styles of moulds flexibly. Equipped with hydraulic cushion, it allows 2mm thickness difference between 2 moulds on one mould station. By fixed mould opening stroke 350mm, it is not affected by any mould thickness changes.

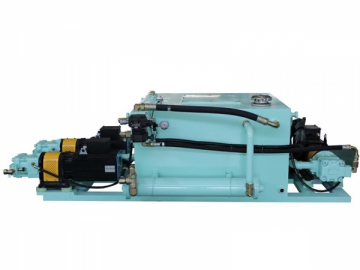

4. Hydraulic System

The hydraulic system reduces noise and promotes efficiency through the use of 3 sets of pump that work individually. These pumps control the pressure and flow rate by using a proportional valve and computer system.

5. Accessories

No need to water circulation for mould station, using efficient heat insulation material.

6. Servo System

The servo system is optional, in order to save energy. The servo system reduces noise, improves the work efficiency and reduces the hydraulic oil temperature, which in turn, extends the service life.

| Item | Unit | KM-E06L2 | KM-E08L2 | KM-E10L2 |

| Work Stations | 6 | 8 | 10 | |

| Mold Clamping Force | kg | 170000 | 170000 | 170000 |

| Mold Opening Stroke | mm | 350 | 350 | 350 |

| Mold size | mm | 290×550×2set | 290×550×2set | 290×550×2set |

| Standard Mold Thickness | mm | 100-330 | 100-330 | 100-330 |

| Heating Power of Mold | kw | 12.28 | 12.28 | 12.28 |

| Screw Diameter | mm | 60/65 | 60/65 | 60/65 |

| Max. Injecting Capacity | cc | 980/1150 | 980/1150 | 980/1150 |

| Injecting Pressure | kg/cm2 | 1200 | 1200 | 1200 |

| Injection Speed | cm/sec | 10 | 10 | 10 |

| Rotating Speed of Screw | rpm | 0-165 | 0-165 | 0-165 |

| Heating Power of Barrel | kw | 13.5 | 13.5 | 13.5 |

| Heating Power of Mold Plate | kw | 73.68 | 98.34 | 122.8 |

| Electricity | kw | 45 | 45 | 45 |

| Electricity Consumption | kw | 132.18 | 167.24 | 181.3 |

| Using Amount of Oil | l | 800 | 800 | 800 |

| Machine Dimension (L × W × H) | mm | 7885×4700×3040 | 9685×4700×3040 | 11485×4700×3040 |

| Machine Weight | kg | 26000 | 32000 | 38000 |