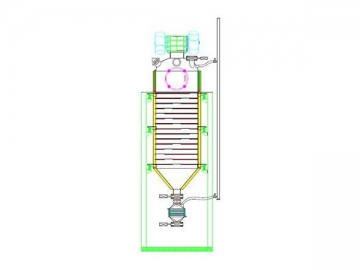

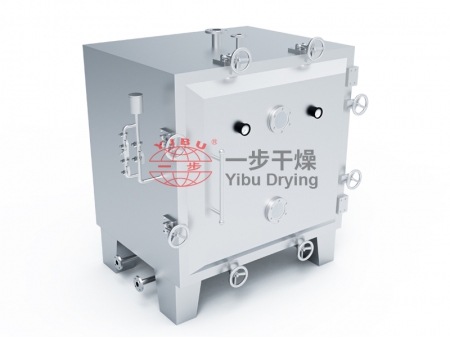

Cylindrical Vacuum Dryer

Description

The cylindrical vacuum dryer is designed to dry the raw material in a vacuum condition during the heating process. The drying machine uses a vacuum pump to damp and create a vacuum state within the chamber. This greatly increases drying speed and minimizes energy consumption.

Our vacuum dryers are divided into static and dynamic dryers. The FZG round vacuum dyer and YZG square vacuum dryer are static dryer systems. The SZG double cone rotating vacuum dryer is a dynamic drying system. Raw material dried in a static dryer is kept undisturbed as to prevent any damage to the material. Dynamic dryers turn the material over and over to dry better and more uniformly.

In a vacuum state, the boiling point of the raw material is significantly lowered. This is ideal for situations in which the material that is being dried is unstable or thermally sensitive. The vacuum dryer is airtight, making it suitable for drying materials that contain irritants and toxic gases, especially if those gases need to be recovered.

Applications

These vacuum dryers are designed for drying heat sensitive raw materials for pharmaceutical, chemical and food applications.

Features

1. Higher drying speed at lower temperatures.

2. Ideal for thermally sensitive materials.

3. It can dry toxic materials and even recover solvents.

4. Before drying, it can carry out disinfectant treatment.

5. This is a static drying system.

Technical parameters

Model Selection| Model | YZG-600 |

| Layers of baking support | 4 |

| Layer interval ( mm ) | 81 |

| Tray size ( mm ) | 310×600×45 |

| Quantity of tray | 4 |

| Working pressure inside the support pipes ( MPa ) | ≤0.784 |

| operation temperature of support pipes ( ℃ ) | 35-150 |

| Degree of vacuum inside the chamber when operation in idle ( MPa ) | -0.1 |

| Under the conditions of -O. 1Mpa and 110 ℃ , evaporation rate of water (kg/m2 ·hr) | 7.2 |

| When condenser is used, Model, and power of vacuum pump (kw) | 2X-15A 2KW |

| When condenser is not used, Model, and power of vacuum pump (kw) | SZ-0.5 1.5KW |

| Weight of drying chamber ( kg ) | 250 |

| Inter size of drying chamber ( mm ) | φ 600×976 |

| Outer size of drying chamber ( mm ) | 1135×810× 102 |

| Model | YZG-800 |

| Layers of baking support | 4 |

| Layer interval ( mm ) | 82 |

| Tray size ( mm ) | 520×410×45 |

| Quantity of tray | 4 |

| Working pressure inside the support pipes ( MPa ) | ≤0.784 |

| operation temperature of support pipes ( ℃ ) | 35-150 |

| Degree of vacuum inside the chamber when operation in idle ( MPa ) | -0.1 |

| Under the conditions of -O. 1Mpa and 110 ℃ , evaporation rate of water (kg/m2 ·hr) | 7.2 |

| When condenser is used, Model, and power of vacuum pump (kw) | 2X-30A 3KW |

| When condenser is not used, Model, and power of vacuum pump (kw) | SZ-1 2.2KW |

| Weight of drying chamber ( kg ) | 600 |

| Inter size of drying chamber ( mm ) | φ 800×1247 |

| Outer size of drying chamber ( mm ) | 1700×1045× 1335 |

| Model | YZG-1000 |

| Layers of baking support | 6 |

| Layer interval ( mm ) | 102 |

| Tray size ( mm ) | 520×410×45 |

| Quantity of tray | 12 |

| Working pressure inside the support pipes ( MPa ) | ≤0.784 |

| operation temperature of support pipes ( ℃ ) | 35-150 |

| Degree of vacuum inside the chamber when operation in idle ( MPa ) | -0.1 |

| Under the conditions of -O. 1Mpa and 110 ℃ , evaporation rate of water (kg/m2 ·hr) | 7.2 |

| When condenser is used, Model, and power of vacuum pump (kw) | 2X-30A 3KW |

| When condenser is not used, Model, and power of vacuum pump (kw) | SZ-1 2.2KW |

| Weight of drying chamber ( kg ) | 800 |

| Inter size of drying chamber ( mm ) | φ 1000×1527 |

| Outer size of drying chamber ( mm ) | 1693×1190× 150 |

| Model | YZG-1400 |

| Layers of baking support | 8 |

| Layer interval ( mm ) | 102 |

| Tray size ( mm ) | 460×640×45 |

| Quantity of tray | 32 |

| Working pressure inside the support pipes ( MPa ) | ≤0.784 |

| operation temperature of support pipes ( ℃ ) | 35-150 |

| Degree of vacuum inside the chamber when operation in idle ( MPa ) | -0.1 |

| Under the conditions of -O. 1Mpa and 110 ℃ , evaporation rate of water (kg/m2 ·hr) | 7.2 |

| When condenser is used, Model, and power of vacuum pump (kw) | 2X-70A 5.5KW |

| When condenser is not used, Model, and power of vacuum pump (kw) | SZ-2 4KW |

| Weight of drying chamber ( kg ) | 1400 |

| Inter size of drying chamber ( mm ) | φ 1400×2054 |

| Outer size of drying chamber ( mm ) | 2386×1675× 1920 |

SZ water ring vacuum pump can be used with mechanical pressure increasing pump in order to increase the vacuum environment.

Instruction to ordering

1. When ordering, please choose the desired vacuum dryer, based on your material requirements.

2. Auxiliary parts of the vacuum drying system indicated in the user's manual can be supplied and installed by our factory. Indicate when ordering.

3. For the equipment, our factory will carry out any repairs, replacements or refunds of substandard products.