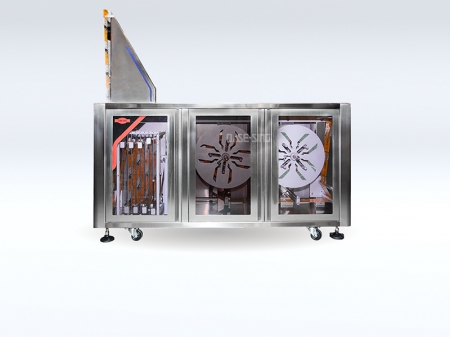

Angle Roll, W24S-320

Juli's W24S-320 angle roll is an excellent 3-roll section bending machine designed with pre-bending function. It provides an easy-to-operate, efficient, accurate and material saving solution for bending all kinds of profiles such as angle steel, channel steel, H steel, flat steel, round steel pipe, square steel pipe, etc. Currently, this angle bending roll has been extensively used in aerospace, petrochemical, hydro power, shipbuilding, automobile, machine manufacturing and steel construction industries.

Features of the Angle Roll

1. The angle bending machine is equipped with a unique control console that can clearly display the positions of lower rolls though a digital screen. Due to that, bending can be completed at a stroke.

2. Driven by hydraulic cylinders, the guide rolls are able to move up and down, forward and backward, and left and right. They are designed to reduce the friction during bending and at the same time avoid twist, thus ensuring bending precision.

3. The machine body is constructed from steel plates by welding and enjoys internal stress relieving treatment. Therefore, the angle roll machine boasts excellent stability, generating smaller vibration and improving bending accuracy.

4. Stand-alone hydraulic system and control console offer high flexibility in operation. They are connected to execution parts of the profile bender by pipes and wires.

5. Bending dies can be customized to fit the specification of your profiles.

6. We can appoint technicians to your place to provide on-site installation guidance and train operators.

| Model | W24S-320 | ||

| Max. bending modulus of section (cm3) | 320 | ||

| Bending speed(m/min) | 3.5 | ||

| Yield limit of material ( MPa ) | 245 | ||

| Inward bending of angle steel | Maximum cross section (mm) | 200×18 | |

| Minimum bending diameter (mm) | 3600 | ||

| Minimum cross section (mm) | 70×6 | ||

| Minimum bending diameter (mm) | 1500 | ||

| Outward bending of angle steel | Maximum cross section (mm) | 200×18 | |

| Minimum bending diameter (mm) | 3600 | ||

| Minimum cross section (mm) | 70×6 | ||

| Minimum bending diameter (mm) | 1300 | ||

| Outward bending of channel steel | Channel steel model | 40 | |

| Minimum bending diameter (mm) | 2000 | ||

| Inward bending of channel steel | Channel steel model | 40 | |

| Minimum bending radius (mm) | 2000 | ||

| Plane bending of flat steel | Maximum cross section (mm) | 360×60 | |

| Minimum bending diameter (mm) | 2000 | ||

| Vertical bending of flat steel | Maximum cross section (mm) | 190×50 | |

| Minimum bending diameter (mm) | 2400 | ||

| Bending of round pipe | Maximum cross section (mm) | 245×8 | |

| Minimum bending diameter (mm) | 3000 | ||

| Bending of round bar | Maximum cross section (mm) | 135 | |

| Minimum bending diameter (mm) | 1800 | ||

| Bending of square pipe | Maximum cross section (mm) | 165×10 | |

| Minimum bending diameter (mm) | 3500 | ||

Related Names

Chimney Making Machine | Filter Making Machine | Automobile Exhaust Pipes Making Machine