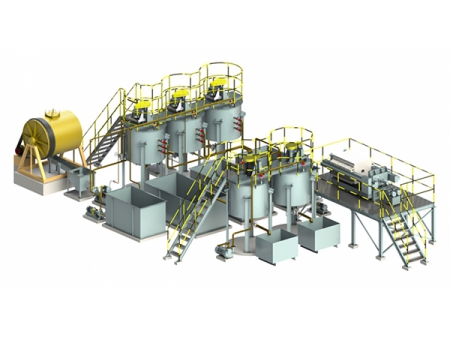

Batch Type Waste Pyrolysis Plant

| Model | | | | |

| Dimension | 1500 ×6600 ×16mm | 2000 ×6600 ×16mm | 2200 ×8000 ×16mm | 2600 ×6600 ×16mm |

| Raw materials | waste tires, waste plastic, waste rubber, and so on | |||

| Structure | horizontal spiral type | horizontal spiral type | horizontal spiral type | horizontal spiral type |

| Processing capacity in 24h | 12m3 | 20m3 | 30 m3 | 35 m3 |

| Pressure | Micro-negative pressure (optional) | Micro-negative pressure (optional) | Micro-negative pressure (optional) | Micro-negative pressure (optional) |

| Rotating speed | 0.4r/min | 0.4r/min | 0.4r/min | 0.4r/min |

| Power | 16kw | 18kw | 20kw | 22kw |

| Cooling method | water cycle | water cycle | water cycle | water cycle |

| Transmission way | Dual drive | Dual drive | Dual drive | Dual drive |

| Noise dB (A) | ≤85 | ≤85 | ≤85 | ≤85 |

| Heating source | coal, gas, fuel oil | coal, gas, fuel oil | coal, gas, fuel oil | coal, gas, fuel oil |

| Working style | intermittent | intermittent | intermittent | intermittent |

| Installation | guidance is offered at the construction site | guidance is offered at the construction site | guidance is offered at the construction site | guidance is offered at the construction site |

| Delivery time | within 25 working days after we have received the down payment | |||

| Installation | within 20 days for clients in China, 25-40 days for clients overseas | |||

| Warranty period | 1 year | |||

| Service life | 5 years | 5 years | 5 years | 5 years |

| Production cycle | 21 working days | 28 working days | 35 working days | 40 working days |

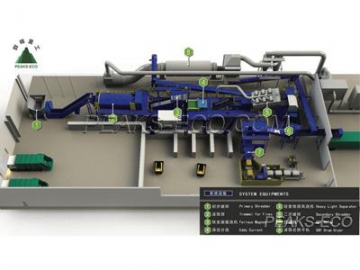

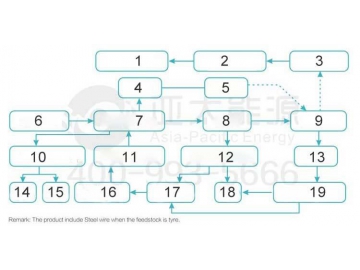

1. Dust Discharge System

2. Counter-Current Wet Dust Removal Tower

3. Waste Gas Whose Heat Has Been Utilized

4. Dust Gas

5. Residual Heat Utilization

6. Auto Feeding Device

7. Micro Negative Pressure Pyrolysis Machine

8. Multistage Separation Tower

9. Multifunction Refining Tower

10. Auto Slag-Out System

11. Gas Recovery System

12. Heavy Oil Collecting System

13. Condenser

14. Carton Black

15. Steel Wire

16. Gas and Liquid Separation Device

17. Micro Negative Pressure System

18. Product

19. Light Oil Receiving System

We put waste tires/plastic/rubber into the pyrolysis furnace of the intermittent pyrolysis plant for high-temperature catalysis and pyrolysis. The mixed gas generated during pyrolysis will pass multistage separator to be filtered and purified. The heavy oil will be separated into storage tank and the light oil will enter the cooling system for condensation, the condensable gas generated in which process will then be transferred to high-quality fuel oil, while those non-condensable part will be guided into a combustible gas recovering system through a unique water seal device developed by ASIA-PACIFIC ENERGY, for powering the pyrolysis furnace.

For the smoke and waste gas produced during the pyrolysis process, ASIA-PACIFIC ENERGY has specially designed an advanced dust removal tower and industrial waste gas purification device to ensure our emission has met the national standards.

The carbon black produced in pyrolysis will be sent to a sealed warehouse by the fully-enclosed spiral and then transferred to carbon black workshop.

1. Advanced Technique

This waste recycling pyrolysis plant adopts advanced pyrolysis technique and comprehensive safety equipment. It features high automation.

2. High Oil Yield

The adoption of pyrolysis reactor allows for uniform heating result, high pyrolysis efficiency, high oil yield, and no gas spillage.

3. High-Efficiency and Environment-Friendly

Our waste recycling pyrolysis plant employs high-efficiency mixed fuel heating system composed of coal, fuel and non-condensable gas. After the purification of dust removal tower and industrial waste gas purification device, the waste gas will reach the national emission standard. The whole system has been tested to meet the highest standards in Europe and USA, and has passed EPI certificate.

4. Rich Experience

ASIA-PACIFIC ENERGY has accumulated many years' experience in producing waste processing equipment. In this field in China, we are the only corporation having got the authorization to set standards and obtained dozens of patents.

5. Energy-Saving

The non-condensable gas produced in pyrolysis can be directly used as fuel for the pyrolysis furnace.

6. High Quality

The byproduct, carbon black can be utilized effectively. It has reached the EPC standard.

7. Wide Applications

The pyrolysis technique is not only suitable for processing waste rubber, waste plastic, waste tires, and waste acrylic, it can also be used for dealing with oil sludge, and oil field waste.

Finished Fuel Oil

Finished Fuel Oil Carbon Black

Carbon Black

a. Finished Fuel Oil

The fuel oil can be sold directly, or used for deep treatment, fuels for boiler heating, bathing, restaurant, and floor tile making, or be processed to organic solvents or vehicle fuels by refining equipment.

b. Carbon Black

It can be sold as fuel directly, or be further treated with refining equipment.