Waste Tyre Pyrolysis Oil Plant

1. High Oil Yield

The adoption of rotary pyrolysis furnace allows for uniform heating result, high pyrolysis efficiency, high oil yield, and no gas spillage.

2. High-Efficiency and Environment-Friendly

Our waste tyre pyrolysis oil plant employs high-efficiency mixed fuel heating system composed of coal, fuel and non-condensable gas. After the purification of dust removal tower and industrial waste gas purification device, the waste gas will reach the national emission standard. The whole system has been tested to meet the highest standards in Europe and USA, and has passed EPI certificate.

3. Mature Technology

The oil-gas cooling system adopts indirect cooling method carried out by cooling tower, which is especially suitable for cooling type fuel oil recovery.

4. Energy-Saving

The non-condensable gas produced in pyrolysis can be directly used as fuel for the pyrolysis furnace, greatly saving fuel sources.

5. High Quality

The byproduct, carbon black can be utilized effectively. It has reached the EPC standard.

6. Wide Applications

The waste tyre pyrolysis oil plant is not only suitable for processing waste rubber, waste plastic, waste tires, and waste acrylic, it can also be used for dealing with oil sludge, and oil field waste.

Waste tire such as machine tires and tire bead etc.

Put the waste tire into the pyrolysis furnace for high temperature catalysis and pyrolysis. The mixed gas produced during pyrolysis will enter the flue gas solid liquid separation equipment for filtration and purification treatment. The heavy components will be separated and then enter the storage tank while the light components will enter the condensing system for further treatment.

The light components will be condensed by the cooling system. The condensed liquid oil will turn into high quality fuel oil. The noncendensable gas will enter the combustible gas recovery system through the water seal safety device. And it will be recycled and used as fuel of pyrolysis furnace.

The flue gas produced during the pyrolysis will enter the advanced flue gas desulphurization and dedusting equipment produced by Asia-Pacific Energy through flue pipe for spray dedusting and cooling. Then it will be discharged after meeting the national standard of harmless emission.

The carbon black generated by the pyrolysis will be pushed out into the sealed stock bin by fully sealed crooked bellows and then enter the production workshop of carbon black.

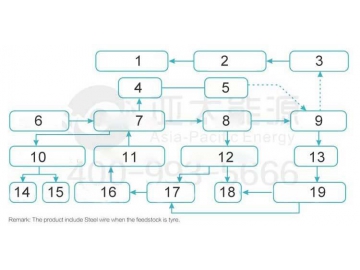

1. Dust discharge

2. Counter-curreng wet dust removal tower

3. Hear ultization waste gas

4. Dust gas

5. Residual-heat ultization

6. Automatic feed

7. Micro negative pressure

8. Multistage

9. Multifunction retiring tower

10. Automatic stag-out system

11. Gas recovery system

12. Heavy oil receiving system

13. Condenser

14. Carton black

15. Steel wire

16. Gas and liquild separation device

17. Micro negative processure

18. Product

19. Light oil receiving system

| Model | Dimension | Treatment capacity in 24h | Engine speed | Power | Noise dB(A) | Manufacturing cycle |

| 150*660m | 12m3 | 0.4rpm | 16KW | ≤85 | 21 workdays | |

| 200*660m | 20m3 | 0.4rpm | 18KW | ≤85 | 28 workdays | |

| 220*800m | 30m3 | 0.4rpm | 20KW | ≤85 | 35 workdays | |

| 260*660m | 35m3 | 0.4rpm | 22KW | ≤85 | 40 workdays |

● Raw material: waste tire, waste rubber, waste circuit board etc.;

● Structure: horizontal rotary;

● Working pressure: micro negative pressure;

● Cooling method: water circulation cooling;

● Driving mode: dual drive;

● Heating mode: coal, fuel gas, fuel oil;

● Working mode: batch type;

● Installation: under instruction;

● Delivery time: within 20 workdays at home and 25-30 workdays abroad.

The terminal products produced from waste tires:

45% tire oil: The tire oil can also be called as fuel oil which can be sold directly or be used as boiler fuel, fuel for bath center, canteen and floor tile calcination. It can also be deep processed into organic solvent and vehicle fuel by refining equipment.

35% carbon black: The carbon black can also be sold directly as fuel. It can also be deep processed by carbon black refining equipment which can be divided into two types: one type of the equipment can produce terminal products of 300-1000 mesh which can be used to produce rubber and tire filler, another type of the equipment can produce terminal products of 1000-2500 mesh which can be used to produce industrial carbon black, printing ink etc.

12-15% steel wire;

5-8% exhaust gas.

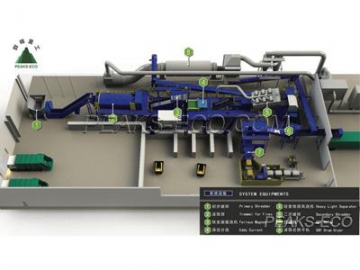

1. Main pyrolysis furnace

2. Mechanical sealing system

3. Power system

4. Multifunction separation equipment

5. Straight type pipe bundle condenser

6. Oil-water separator

7. Residual oil tank

8. Water seal

9. Exhaust recovery system

10. Flue gas dedusting system

11. Power distribution cabinet

12. Water cooling tower