PVC/WPC Pelletizing Line

PVC Pelletizer, Wood Plastic Composite Pelletizing Machine, Plastic Granules Making Machine, Plastic Extruder

-

Plastic pelletizing line for PVC/WPC

-

Plastic pelletizing line for PVC/WPC

-

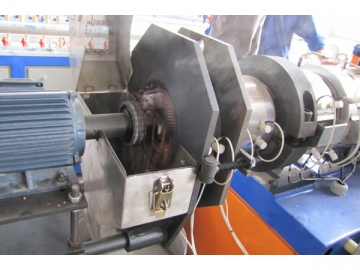

Extrusion head and pelletizer

This PVC/WPC pelletizing line consists of , Conical Twin Screw Extruder pelletizing die head, and stainless steel air cooling device. The die discharging board is made from high-quality alloy steel, 38GrMOALA, and has accepted gas nitriding treatment for high mold durability. The mold case is precisely processed with forged 45 # steel. A uniform extrusion result can be reached with the reasonably-arranged flow channel.

The precision elastic cutter is set to ensure that the section is smooth, and to extend the life of the granulator. With stepless variable speed motor, the plastic pelletizer runs stably and is competent in meeting various speed requirements in different pelletizing process. The unique stainless steel cooling structure, the cyclone separation and cooling system, as well as the combination of several powerful fans, have strongly guaranteed the extruded plastic.

The WPC/PVC plastic pelletizing line is mainly applicable in the pelletizing process of PVC powder or fillers. The extruded plastic particles are compact, uniform and aesthetic. Auxiliary devices of the pelletizing line employ die face cutting, air blowing system for material transport, and vibration separation, supporting a high automation and productivity.

Acceptable materials: PVC, WPC powder, and other additives

-

PVC granules

-

Transparent PVC granules (hard)

-

Transparent PVC granules (soft)

| Model | Screw size (mm) | Pellet size (mm) | Main motor power (kw) | Output (kgs) |

| 55/110 | Ф3-4 | 22 | 40-180 | |

| 65/132 | Ф3-4 | 37 | 50-250 | |

| 80/156 | Ф3-4 | 55 | 200-400 | |

| 92/188 | Ф3-4 | 110 | 300-750 |

| Model | |||

| Screw speed | 1-36r/min | ||

| Total Installed capacity | 48KW | 72KW | 100KW |

| Max. Extrusion capacity | 50-220kg/h | 150-360kg/h | 400-600kg/h |