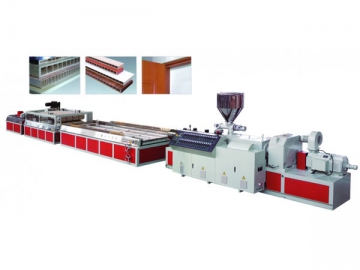

WPC Door Panel / PVC Hollow Thermal Tiles Extrusion Line

Production Line for WPC Hollow Tile, WPC Door Plate Extrusion Line, Plastic Plate Extrusion Line

MSSZ series WPC Door Panel / PVC Hollow Thermal Tiles Extrusion Line is designed with different specifications of twin/single screw extruder and material prescription, according to different plate sections and applications. Auxiliary devices like vacuum sizing machine, traction machine, transverse cutting machine, and stacker are optional. Operators can use this plate extrusion line to produce diversified WPC plates simply by using different molds.

The traction machine is specially developed by Zeqi and is of stable performance, high reliability, and large traction force. The vacuum sizing machine utilizes a particularly-enlarged swirl cooling system to meet the production of wide WPC plates. The transverse cutting device is designed to move synchronously with the plates. A dust recycling system is set to prevent pollution.

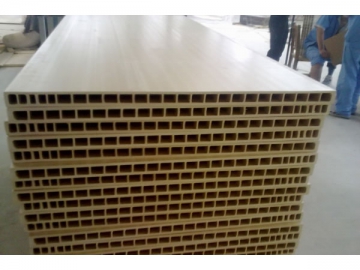

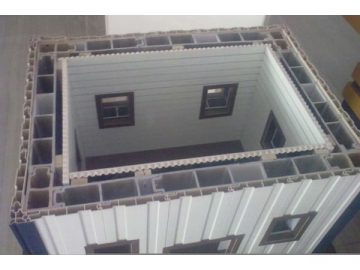

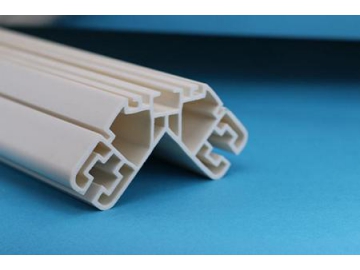

Applications: for producing WPC door plates, WPC Partition board, and PVC heat insulation hollow tiles, etc.

Corrugated tiles

Advantages of WPC Hollow Tiles

Comparing with traditional plastic tiles, PVC hollow corrugated tiles perform better in heat resistance, noise insulation, corrosion resistance, and rust protection. They are especially suitable for tropical weather. WPC hollow tiles are tough, durable and are easy to be installed. Their rigidity is largely improved in comparison with conventional plastic tiles. WPC hollow tiles are ideal for agricultural greenhouses, factories (chemical and pharmaceutical), playground, warehouses, schools, marine uses, and commercial buildings, etc.

| Model | ||

| Screw diameter (mm) | 80/156 | 92/188 |

| Main motor power (kw) | 75 | 110 |

| Max width (mm) | 820 | 1100 |

| Max extrusion capacity (kg/h) | 180-360 | 350-700 |