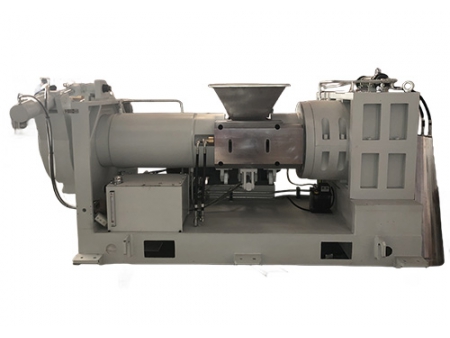

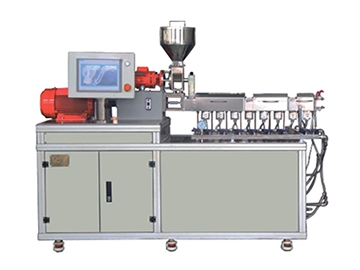

Extruder (for Feed Production)

Capacity: 3~10T/H

Model No.: SHSP165, SHSP185, SHSP215

Many confuse an extruder with a pellet mill. Though they both work at a particular level of moisture, temperature, and pressure to form pellets, they are like poles apart and don't even look the same. The extruder mixes materials in a screw barrel while a pellet mill uses rollers to force raw feeds through holes of a flat die or ring die. The feed extruder can be used on a variety of feed and food processing lines, and according to the kind of formulation used, operators can adjust the screw configuration to produce different extruded feed products.

Features of Feed Extrusion Machinery

1. Industry-leading expansion technology uses intelligent control to ensure easy operation.

2. Variable speed conditioner comes with twin drive shaft made of stainless steel. Up to 12 steam-injection ports and 6 liquid injection ports are arranged along the barrel of the conditioner.

3. Main drive shaft can be taken part for easy repair and gearbox maintenance.

4.Involute splines are used to connect between the screw and main drive shaft for easy screw adjustment and change.

5. Wear-resistant liners are fitted inside the screw barrel which is effectively cooled or heated by the re-circulating water jacket.

6. Die head can be changed out easily. In-line adjustment of the cutting device.

7. Specifically suitable for pelleting 2-6mm diameter floating grains.

| Model No. | Main Motor Power (KW) | Feeder Power ( kw ) | Conditioner Power (KW) | Cutting Power (KW) | Capacity (T/H) |

| 132/160 | 2.2 | 15/18.5 | 4 | 3-5 | |

| 185/200 | 2.2 | 18.5 | 5.5 | 4-7 | |

| 250/285 | 3 | 22 | 7.5 | 6-10 |