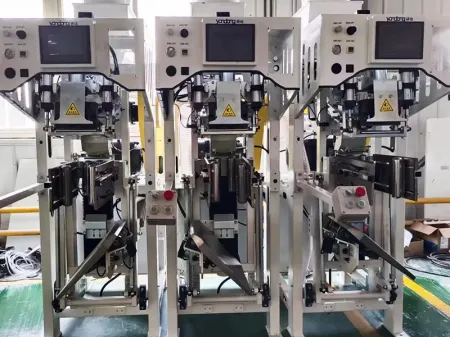

Metal Tube Filler and Sealer, ZHF-80Z

Automatic Metal Tube Filling and Sealing Machine, Aluminum Tube Filling Machine, Automatic Metal Tube Filler, Auto Metal Tube Filling & Sealing Machine

Features of the Auto Metal Tube Filler & Sealer

1. Variable frequency drive

2. Tube end shapes of the metal tube filling & sealing equipment can be processed into 2-fold, 3-fold, and saddle-shaped styles by one machine

3. The manipulator allows for a flexible and reliable sealing process. The tube filling and sealing parts are open type, making it easy to be cleaned and maintained

4. The photoelectric sensor imported from Germany cooperated with high-precision driver and stepper motor (servo motor is required for high labelling demands) are used to ensure a right tube labelling position

5. With the filling nozzle extended into the tube, the materials are filled gradually, ensuring that there will be no leakage or overflow. The fine-turning hand wheel is mounted outside the Aluminum tube filler and sealer so precision adjustment would be convenient, with the filling deviation no more than 0.5%. Zhonghuan auto filling & sealing device can fit the filling requirements of different kinds of materials

6. The large-power mixing device mounted inner the material hopper adds safety and reliability to the liquid filling machine. The hopper insulation system is consisted of both water temperature control device and hopper

7. The air compressor in the tube end employs the multi-stage filtration mechanism (oil-gas filter is adopted to keep the compressed air clean)

8. Uniform standards are made for the lubrication system to ensure the smooth running of the Aluminum tube filling and sealing machinery as well as to protect the working environment from pollution.

Technical Parameters

Filling capacity: 60-80 tubes/min

Filling volume: 2-200 ml/unit (adjustable)

Tube diameter: 10-35 mm

Tube length: 50-200mm

Filling accuracy: ≤0.5﹪

Power: 1.5kw

Working pressure: 0.6PMa

Dimension: 2270×960×2100 (mm)

Weight: 1200 kg

Applications

This kind of filling and sealing machine is designed for products that utilize tubes as the packaging container. It is widely accepted in cosmetic, household chemical, pharmacy, and food industries. With this machine, different kinds of viscous liquids like ointments, creams, and gels can be filled and sealed in the soft tubes.

Wenzhou Zhonghuan Packaging Machinery Co., Ltd.

Tel.: