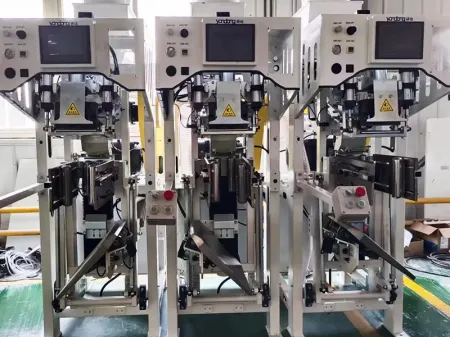

Automatic Tube Filler and Sealer, ZHNG-100A

Tube Filling and Sealing Machine, Automatic Chemical Filling and Packaging Line, Auto Tube Filling Machine

Features

1. For this auto tube filling and sealing machine, the tubes are pressed into the positioning plate automatically

2. The tube filler & sealer adopts springs to ensure the same height of sealed tube end

3. It uses automatic color identification systems to mark the position of oval or other special-shaped tubes precisely

4. Mechanical driving method is adopted in the automatic tube filling line to ensure the stability of tube feeding

5. Rising positioning plate is adopted for tube filling

6. The air heater is from LEISTER for reliable quality

7. The tube filling and sealing equipment will heat the inner wall of the tube end and cold the outer side to ensure an excellent sealing effect

8. Exhausting the harmful gases with fans (made in Taiwan)

9. With an air-cooling system, the heat will not be transferred to the viscous liquids after sealing

10. PLC fully automatic control system is adopted for the tube filling line

11. This auto filling and sealing machinery employs high-definition digital display and stainless steel equipment frame

12. A connection between the emulsifier and the filling machine can be easily achieved

13. Treatment for different tubes with different diameters is variable

14. The operations of viscous material filling, tube sealing, and printing can be done by one machine automatically

15. Operations of tube feeding, cleaning, label positioning, filling, and sealing are finished automatically

16. Stepless speed control is adopted for the automatic tube filling machine; with a large tube inventory, the tube feeding process will be carried out continuously

17. Controllable product quantity

18. A mechanical hand is set to print codes on the prescribed position automatically

19. The parameters are showed and controlled through a digital display

20. The auto tube filling system features console model and large-amount tube supply

21. Vacuum generator is employed to control the tube adsorption positioning device

22. The photoelectric sensor from Omron is adopted in the tube direction examination system to test the tube position accurately

23. Cam indexing drives method is utilized

24. Automatic cleaning and dust recycling system

25. Both malfunction alarming and over-loading stopping device are employed for the automatic tube filling and capping equipment

26. When filling is finished, the tube end will be cooled down with an air blower to guarantee the filling effect

27. Column model heat preserving and mixing system (optional)

28. With the automatic ultrasonic wave material-position detection system and the module from Siemens, the material position will be accurately detected and showed on the touch screen (optional)

29. The machine will stop filling if there is no tube

Technical Parameters of the Auto Tube Filling & Sealing Machinery

Metal tube diameter: 10-35 mm

Diameter of plastic tube and compound tube: 10-60 mm

Metal tube volume: 1-150 ml

Volume of plastic tube and compound tube: 1-250 ml

Production capacity: 60-100 tubes/min

Filling precision: ≤±1%

Power: 2.2kw

Air pressure: 0.4-0.6 MPa

Applications

This series of auto tube filling and sealing machine is mainly applied in plastics tubes, compound tubes and metal tubes.

Wenzhou Zhonghuan Packaging Machinery Co., Ltd.

Tel.: