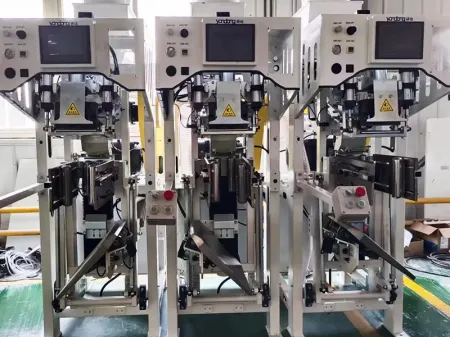

Automatic Tube Filler and Sealer, ZHF-100YC

Auto Tube Filling and Sealing Machine, Auto Tube Filler, Automatic Chemical Packaging Machine, Automatic Toothpaste Packaging Machine

This filling and sealing machine adopts PLC control system to realize an automatic production process. It is designed with the functions of auto tube feeding and precise label positioning. The nozzle will enter inside the tubes which have been cleaned completely to fill in the viscous liquids. Then the tube filler & sealer will heat the inner wall of the tube end while cool the outer side using a chiller. After a series of hot-pressing, printing, and trimming operations upon the tube end, the finished tubes will be discharged. The parameters are displayed digitally.

Features

1. Variable frequency control is employed for the tube filling equipment

2. The hot air generator imported from Switzerland provides stable heat source for the tube end

3. We set a ring heater to heat the inner wall of the tube end and an annular cooling water jacket for cooling the outer wall, ensuring that the tube end is heated evenly. In this way the tube will feature good sealing and printing result

4. This auto tube packaging machinery commits a highly-precise printing and labelling result since we have equipped it with the photoelectric sensor imported from Germany, cooperated with a high-accuracy driver and a stepper motor

5. For viscous material filling, the nozzle will reach into the tube and fill in the liquids gradually, during the period of which no leakage or overflow phenomenon will occur. Our automatic liquid filler & sealer is suitable for the filling requirements of diversified materials. The fine-turning hand wheel is mounted outside the machine for convenient adjustment, with the filling precision within ±0.5%

6. A large-power mixing device is mounted in the material hopper for high security degree and wide applications. The hopper insulation system is comprised of water temperature control device and hopper, etc.

7. The trimming methods upon the tube end are varied according to different tube materials and end shapes. There will be no burrs on the trimming part

8. Multi-stage filtration system (oil-gas filter device is used to ensure the cleanness of compressed air) is employed for air compressing

9. Customizable lubrication system is adopted for our auto filling and sealing equipment

| Filling volume | 1-400 ml/unit (adjustable) |

| Filling accuracy | ≤±1﹪ |

| Capacity | 3600-4800 tubes/hour (adjustable) |

| Tube diameter | Φ12-Φ60 mm |

| Tube length | 50-240 mm |

| Hopper volume | 40L |

| Power supply | 380V /220V (optional) |

| Air pressure | 0.4-0.6 MPa |

| Equipped motor | 1.1kw |

| Machine power | 5kw |

| Inner wind motor | 0.37kw |

| Convulsions motor | 0.37kw |

| Dimension | 2270×960×2100 (mm) |

| Weight | 1350 kg |

Applications

Zhonghuan auto filling and sealing machine has found applications in many industries like cosmetics, household chemical, pharmacy, and food. It is an ideal for products that utilize soft tubes as the packaging containers. Various viscous fluids including ointment, cream, and gels can be filled into the tubes with this equipment. Also the tube ends will be printed and trimmed into an aesthetic shape.

Cautions

Operating procedures of the liquid filling & sealing machine:

Auto tube feeding → label positioning → inner tube cleaning (optional) → material filling → tube end hot melting → sealing → printing → trimming → finished tubes discharging

Wenzhou Zhonghuan Packaging Machinery Co., Ltd.

Tel.: