Steel Pipe Reducer

Reducer is an important coupling in piping system to connect pipes that have different inside diameters. It is classified into concentric reducer and eccentric reducer. Concentric type is generally applied in vertical pipes, and eccentric reducer is mainly used for horizontal pipeline system.

Pipe reducer is indispensable when there is a flow change of little flow rate in the pipeline to avoid failure. Or it can be used at the inlet of a pump to prevent cavitation. For some meters like flow meter, pipe reducer is applicable in connecting the meter with control valves.

Concentric or eccentric reducers are generally fabricated with reduction molding, expansion molding, or reduction &expansion molding techniques. For some reducers with certain specifications, forging technique is acceptable. Basing on the reduction and expansion techniques, the span of pipe reduction is up to level 4, and for some common specifications like DN100, DN125, and DN150, it is level 5.

- Eccentric reducer

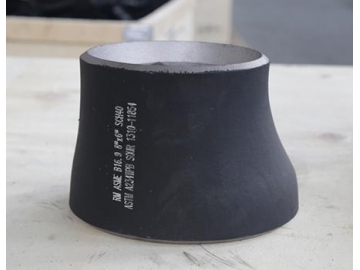

Concentric reducer

Concentric reducer Concentric reducer (Thick wall)

Concentric reducer (Thick wall) Eccentric reducer (Thick wall)

Eccentric reducer (Thick wall)

Reducer made from pipe is manufactured with diversified cold or hot processing techniques like bending, extrusion, molding, and machining. The basic principle for choosing molding techniques is that it should do no harm to the fittings. The production range is listed in the table:

| Type | Nominal diameter | Wall thickness | |

| Seamless pipe reducer | 1/4"~24" | DN8-DN600 | 1.5~26mm |

| Welded pipe reducer | 1/2"~24" | DN15-DN600 | 1.5~26mm |

This piper reducer is manufactured with cold or hot stamping technique from steel sheets or strips. Considering the different requirements of nominal diameter and manufacturing technique, the reducer is allowed with 1 or 2 longitudinal seams on its body.

| Type | Nominal diameter | Thickness | |

| Die stamped reducer | 10"~100" | DN250-DN2500 | 1.5~30mm |

| Austenitic stainless steel | Super duplex stainless steel | Nickel-based alloy steel | Carbon steel/alloy steel | Other materials |

| 304 304L 304H 304LN | S31803 S32205 | N10276 N04400 N06600 | Q235 20# 20G | TA1 TA2 TA3 TC1~TC9 |

| 316 316L 316H 316Ti | S32304 S32760 | N06600 N06625 N06690 | WPB A105 16Mn | LF2 LF3 LF5 LF6 LF10 |

| 310S 321 321H 347 | S32550 S32750 | N08800 N08825 N08904 | 45# 15CrMo | Al, Ti, martensite |

| S31254 | S33400 | N08020 N08810 N08811 | A350LF2 A420Gr.WPL6 |

Advanced equipment is vital to products’ quality. So Yuanyang has introduced over 300 sets of large processing equipment in our factory, including precise forging equipment, metal cutting machine, hydraulic press, automatic welding machine, and surface treatment equipment, just to name a few.

Yuanyang’s commitment to quality is evident in every step of our process: the steel pipes, strips, bars, and sheets are purchased from trustworthy manufacturers; raw materials are marked with different colors so that they are easily distinguished; and 100% spectral detection is conducted for all of the finished fittings before shipping.

As a pipe fitting manufacturer, Yuanyang has obtained the Special Equipment (Pressure Pipe Fittings) Manufacturing License from the General Administration of Quality Supervision, Inspection and Quarantine. Additionally, our pipe fittings have passed the certificates of ISO9001: 2008, ISO14001: 2004, OHSAS18001: 2007, PED, and AD2000, and have been certified by Classification Societies in different countries like the USA (ABS), France (BV), China (CCS), Canada (CRN), Norway (DNV), Germany (GL), and the UK (LR).

Manufacturing standards| Seamless steel butt weld pipe fittings: | SH3408 |

| Seamless steel fittings: | GB/T12459 |

| Butt weld elbows for marine use: | GB/T10752-1995 |

| Titanium/titanium alloy seamless and welded fittings: | GB/T27684 |

| Steel butt weld fittings for piping: | JIS B2312 |

| Factory made butt weld fittings: | ASME B16.9 |

| Socket weld fittings made from forged steel: | GB/T14383 |

| Socket weld fittings made from forged steel: | SH3410 |

| Socket weld fittings and threaded fittings: | ASME B16.11 |

| Austenitic stainless steel pipe fittings: | ASTM A403/A403M |

| Butt weld fittings: | DIN EN 10253-3 (forged Austenitic stainless steel and duplex Austenitic stainless steel with no special inspection requirements) |

| Butt weld fittings: | DIN EN 10253-4 (forged Austenitic stainless steel and duplex Austenitic stainless steel with special inspection requirements) |