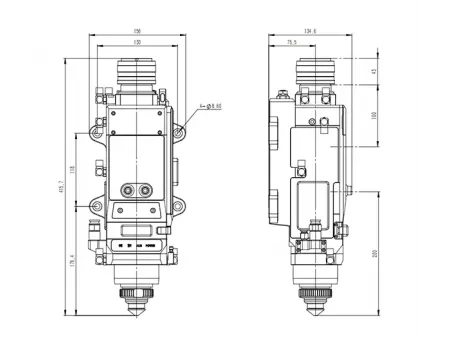

20kW Fiber Laser Bevel Cutting Head

GH20B

Intelligent information auto focus laser cutting head for processing thick metal plates with power ratings of up to 20kW

GH20B

Intelligent information auto focus laser cutting head for processing thick metal plates with power ratings of up to 20kW

This high-power smart fiber laser cutting head is designed for thick metal plate cutting with power ratings of up to 20kW. Equipped with 5G communication, it enables real-time monitoring of gas pressure leakage, lens contamination, and nozzle temperature. The system provides timely alerts and automatic collision protection with emergency shutdown, reducing maintenance needs while improving overall cutting efficiency. The water-cooling design ensures stable operation during long production cycles.

| Type | Auto Focus Smart Fiber Laser Cutting Head |

| Model | GH20B |

| Interface Type | QBH,QD,Q ,LOE/QF-D |

| Wavelength | 1080±10nm |

| Rated Power | ≤20kW |

| Focal Length | 200mm/250mm/300mm |

| Collimation Length | 100mm |

| Focusing Range | -39mm~ 30mm |

| Centering Adjustment Range | ±1.5mm |

| Focusing Speed | 200mm/s |

| Auxiliary Gas Pressure | ≤3MPa |

| Weight | 7kg |

The 20kW auto focus smart cutting head is ideal for thick metal plate processing. It supports cutting of carbon steel, copper, aluminum, and galvanized sheet, making it suitable for demanding heavy-duty manufacturing environments.

- Cutting 25mm carbon steel, 13kW

- Carbon steel

- Carbon steel

High-temperature alarm automatically issues a shutdown command that ensures timely stop and alerts the operator to troubleshoot, preventing processing defects.

Continuous transmission of nozzle temperature data dynamically adjusts cutting height maintains a consistent distance between nozzle and workpiece for stable cutting quality.

Real-time lens temperature control allows automatic focus adjustment that prevents focus drift caused by lens heating, ensuring uniform cutting performance.

Alarms are triggered if cutting gas pressure is abnormal, preventing damage and poor cutting caused by low or missing gas pressure.

Detects differences between actual and set cutting gas pressure, and calibrates pressure automatically to ensure consistent cutting quality and protecting the head.

Issues an alarm if the laser protection window seal fails and reminds operators to service or replace parts, preventing internal lens contamination.

Built-in sensor with dedicated blowing assembly that protects the laser head upon collision, while triggering an immediate shutdown signal.

Monitors piercing results in real time. Cutting begins immediately after penetration, eliminating delays and boosting productivity.

Alerts when lenses become contaminated, with both warning and shutdown modes. This prevents poor cutting quality and laser head damage by ensuring timely lens replacement.