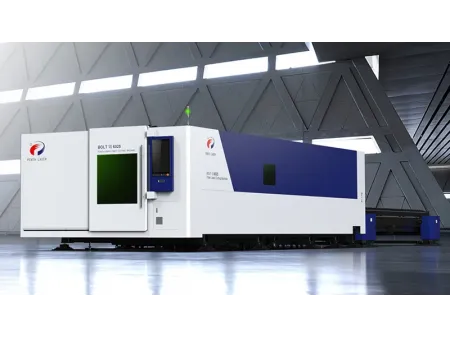

BOLT VII Fiber Laser Cutting Machine

Sheet metal laser cutter for processing various metal materials

Our BOLT VII (Enclosed, 6-85kW) fiber laser cutting machine boasts the ability to precisely cut a diverse array of materials including metals and plastics. Engineered for peak performance, it can reach 2.8G-4.0G acceleration, underpinned by the specialized SM system for enhanced automation solutions. Renowned for its high power efficiency and minimal maintenance requirements, the BOLT VII is an ideal choice in sectors such as metal processing, automotive production, and electronics manufacturing.

- Laser power6,000W-85,000W

- Working area (L×W)3000×1500mm-13000×3000mm (optional)

- Applicable materialsStainless steel, carbon steel, aluminum alloy, brass, copper, and various types of alloy

As a leader in the Chinese laser industry, PENTA LASER specializes in the design and manufacture of high performance laser machines for a wide range of industries, including automotive, shipbuilding, agricultural machinery. Contact with us for a full custom laser engineering solution.

- Structural Steel

- Heavy Machinery

- Shipbuilding

- Aerospace

- Oil Equipment

- Railcar

- Transmission Tower

- Ultra-high laser power (6-85kW)

- Stable operation with detached bed design

- Precise touchscreen control with SM system

- 4G acceleration

- Intelligent water-cooled cutting head for cutting stability

- Advanced 16-section dust collection for cleaner and safer work environment

- Automatic gas distribution device ensuring precise control of auxiliary gases' flow and pressure

| Laser power | 6,000W-85,000W (optional) |

| Working area (L×W) | 3000×1500mm-13000×3000mm (optional) |

| Maximum acceleration | 2.8G-4.0G |

| Maximum running speed | 200m/min; 240m/min (depending on machine model) |

| Mechanical repeatability | 0.06-0.08mm |

| Laser source option | IPG/RAYCUS/MAX/JPT |

Laser Head

The Bolt7 features an exclusive laser head developed in collaboration with PRECITEC, designed for swift power escalation without compromising the power of the laser beams.

Separate Bed

Utilizes a gantry for more flexible and efficient operation. The workbench's separation from the bed minimizes internal stress, ensuring longevity and stability.

Lightweight Beams

The steel beam is used to ensure the high rigidity, thus enabling the beam capable of long-term cutting without being deformed, and the cutting accuracy is more stable.

We are always ready for supporting you about laser machines and systems