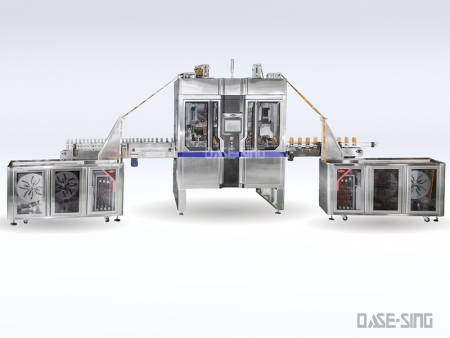

i-Sleeve Pro II Double Head Shrink Sleeve Labeling Machine

Automatic shrink sleeve label applicator for speeds up to 1000BPM

i-SleevePro II double head shrink sleeve labeling machine is currently the fastest dual-head shrink sleeve labeling machine offered by us. It boasts a top speed of up to 1000 BPM/180mm (standard length). The automatic shrink sleeve label applicator is compatible with PET 30um and PVC 32um thin labels, reducing the cost of shrink film materials and providing convenience in sealing various bottle and can openings. The dual-head labeling feature allows the label applicator machine to simultaneously apply two different labels at different positions, thereby enhancing operational efficiency.

- Maximum Speed: 1000 BPM

- Bottle Outer Diameter: Ø25mm to Ø125mm (based on customer-provided bottle specifications)

- Film Material: PVC / PET / OPS

- Film Thickness: PVC: 0.032mm to 0.07mm, PET: 0.02mm to 0.06mm, OPS: 0.04mm to 0.06mm

- Machine Dimensions (L×W×H): 2000mm x 1327mm x 2845mm (our company reserves the right to modify the machine's dimensions for equipment optimization)

- Voltage: 3-phase; 220V, 380V, 415V, 440V (depending on customer requirements)

- Compatible Containers: Supports a wide range of container shapes, including round, oval, square, and more.

- Comprehensive integration with production lines, featuring protective covers and a color human-machine interface (HMI) for parameter setting, making it easier to manage production lines.

- Unique knife plate design eliminates the need for changing knife plate within the specified range; if replacement is necessary, it can be done rapidly within minutes.

- Forced insertion design helps save production costs.

- Integrated design for easy adjustment of the entire machine's transmission mechanism when handling labels of various specifications.

- PLC control for improved labeling accuracy and speed.

- Can use 20um thin shrink labels, significantly reducing shrink film material costs. The labeling speed for the dual-head labeling unit can reach 650 BPM/180mm (standard length), while the single-head labeling unit can achieve a speed of 350 BPM/180mm (standard length).

- The shrink sleeve labeling machine can still complete labeling when the conveyor belt speed changes.

- Optional UWI-8 floor-standing label unwinder extends material replacement time, increases production efficiency, and reduces labor costs.

- First head and second head can operate simultaneously, achieving a labeling speed of up to 1000 BPM/180mm (when compatible with the conveyor and feeding systems).

- When one of the labeling heads is undergoing maintenance, experiencing an issue, or changing labels, the other head can continue production at a speed of up to 650 BPM/180mm.

- First and second heads can label different parts simultaneously and separately. For example, one head can label the bottle body while the other head labels the bottle neck, all completed on the same labeling line.

- When the first head is in production and the second head is in a READY state (ready to operate), if an issue occurs with the first head, the second head can automatically begin production without reducing production efficiency.

- Neck Tamper Evident Banding Used for sealing bottle necks, preventing tampering, and maintaining product integrity.

- Full Body Over-The-Cap Sleeve Labeling Labels cover the bottle neck, body, and bottom, commonly used for sauces, condiments, and similar products.

- Full Body Shrink Sleeve Labeling Labels cover from the lower edge of the bottle neck to the bottom, commonly used for juices, coffee, and more.

- Partial Body Shrink Sleeve Labeling Labels are positioned in the center of the bottle body, commonly used for various bottled and canned products.

- Full Body & Underlap Sleeve Labeling Designed for products requiring labeling to the bottom, enhancing product aesthetics and presentation.

The i-Sleeve pro II double head shrink sleeve labeling machine is ideal for high-efficiency labeling demands and is suitable for a variety of product packaging applications, including:

- Beverage bottles: Water, juice, tea, and more

- Pharmaceutical bottles

- Cosmetics and health product packaging

- Other Fast-moving consumer goods (FMCG) packaging