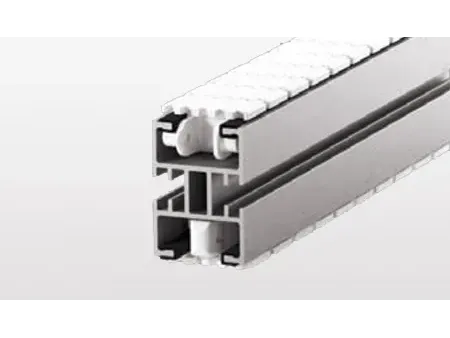

CXS Modular Plastic Chain Conveyor

44mm Chain Width

- Beam width: 45mm

- Chain width: 44mm

- Chain pitch: 25.4

- Chain tension limit/tensile strength: 500N

- Maximum item weight

- Horizontal transport: 2kg

Vertical transport: 1kg - Maximum conveyor load: 150kg

- Maximum conveyor length: 30m

- Materials: aluminum/stainless steel

*The conveyor components may vary, and the conveyor system can be configured with suitable chains according to the production requirements, e.g., temperature, strength, etc.

Our CXS plastic chain conveyor system features modular design, which increases the flexibility, convenience and efficiency of material conveyor systems and suits the various uses across production lines within factories.

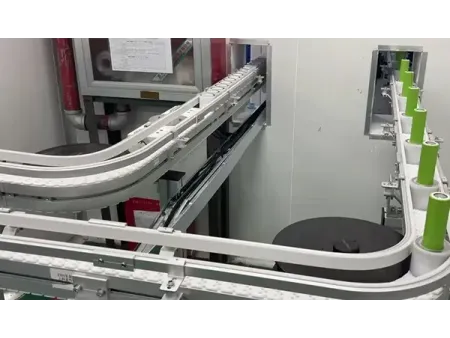

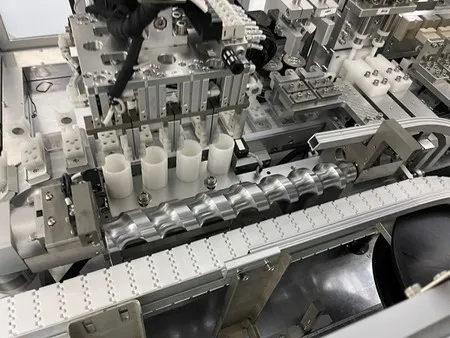

Contrary to the traditional conveyor systems, our modular conveyor system uses a series of connected plastic chains/modules that function as a belt. Individually replaceable, this reduces the duration of maintenance and downtime of production lines, improving work efficiency and effectiveness. Highly convenient, the modular plastic chain system can be applied to move products across various industries. The conveyor system is built with a design of compact vertical bends to optimize floor space utilization and to support multi-level transportation, making the conveyor easily accessible to operators. The standard conveyor chain width is 44 millimeters, accommodating a wide range of products of diverse weights and shapes, up to 8 kilograms.

- Fast and customizable conveyor solutions: To streamline your conveying operations and improve production flow and product quality, we use standard components to design customized conveyor solutions tailored to the unique needs of each customer. This approach allows for efficient design and assembly processes, enabling the faster delivery of customized conveyor solutions.

- Compatibility and flexibility: For our customers' flexibility of choice, our lines of plastic chain conveyors are designed to fit multiple conveyor systems from other conveyor manufacturers, including well-known brands such as Flexlink, FlexMove, and Rexroth.

This modular plastic chain conveyor is suitable for conveying various types of packed products, both small pieces and bulk products, such as small ball bearings, perfume bottles, medicine bottles, aerosol cans, batteries, metal sintered parts, etc. The conveyor can be used for warehouse distribution in various industries including logistics pharmaceuticals, cosmetics, food & beverage, etc.

- Battery Conveyor

- Modular Conveyor for Smart Meter

This modular plastic chain conveying system includes conveyor chains, conveyor beams, end drive units, idler end units, horizontal plain bends, and other various conveyor components. Each component is available in a range of options, ensuring flexibility for your conveying needs.

- Conveyor chains

- Conveyor beam

- End drive units

- Horizontal bend drive unit

- Idler end unit