Three Roller Coater

Request a Quote

Surface finishing system with three coating heads for large format panels

The three roller roll coater accomplishes coating with the use of 3 sets of coating heads. It is widely used for coating large area panels and strips, such as floors, cabinet panels, and furniture panels. This machine results in a thicker coating with the use of multi-roll coating processes, with the coated panels featuring a glossy surface. Suitable materials include wood, glass and metal panels, plastic film, melamine plates, and plywood.

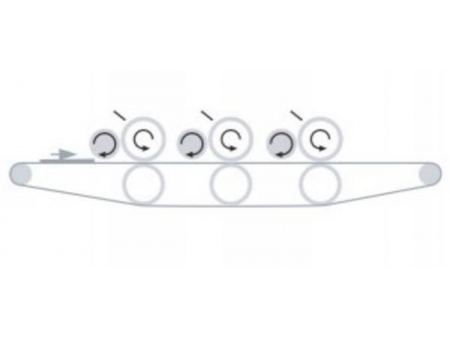

Working principle

The doctor roll ensures the coating is distributed uniformly along the coating roll, and then ensures the coating roll evenly applies the coating to the product surface.

Specifications

| Effective processing thickness | 2-80mm |

| Effective processing width | 620/920/1320mm(optional) |

| Minimum processing length | 300mm |

| Transport speed | 0-20m/min |

| Heating power | 3kW |

| Power supply | 380V/50Hz |

| Paint type | UV/Water-based/PU/NC/PE |

Details

- The conveyor belt, coating roll and doctor roll are all controlled by independent DC converter motor that carries out a precise stepless adjustment. It is suitable for roll coating with UV paints.

- Important parts and components of the roller coater are formed through a casting process that uses self-designed molds, depending on application requirements. For instance, split type casting is used as the roller bearing seat in order to ensure roller replacement is fast and easy.

Optional models

| Model | Effective processing width (mm) | Conveying power (kw) | Power of coating roll (kw) | Power of doctor roll (kw) | Outline size (L*W*H) |

| 620 | 0.75 | 0.75 | 0.55 | 1800*1850*1700 | |

| 920 | 0.75 | 0.75 | 0.75 | 1800*2150*1700 | |

| 1320 | 1.5 | 1.5 | 0.75 | 1800*2450*1700 |