Pressure Type Granulating Spray Dryer

Description

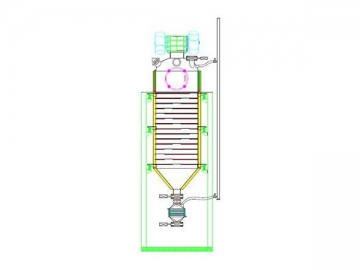

The YPG series pressure type granulating spray dryer is specially designed for drying and granulating at the same time. Granules of a certain size and ratio can be created with this drying equipment by adjusting the pressure, flow and size of the atomizing hole. The tower body features an insulated design for heat preservation and an observation door.

Heat source: steam, electric, gas fuel or oil fuel (for gas or oil, it must be equipped with air heating furnace)

Application

1. Granulating through atomization drying: chemical industry, organic catalyst, resin, synthetic, washing powder, oils, thiamin, dyestuff, intermediate of dyestuff, white carbon black, graphite, ammonium phosphate and so on.

a. Foodstuff: amino and similar substance, flavoring, protein, starch, diary products, extractive substance from coffee, fish powder, extractive substances from meat, etc.

b. Pharmaceutical: Chinese patent medicines, agrochemicals, antibiotics, medical drinking agent, etc.

c. Ceramics: magnesium oxide, kaoline, all kinds of metallic oxide, dolomite, etc.

2. Granulating through atomizing: all kinds of fertilizer, aluminum oxide, ceramics powder, pharmaceutical, heavy metallic super hardness steel, chemical fertilizer, washing powder, Chinese medicines, etc.

3. Granulating through atomized cooling: amino acids, paraffin wax, glycerate, tallow, etc.

Features

1. Fast drying speed. Liquid material after atomization will increase its surface area largely and can evaporated its moisture 95%~98% instantly. Drying time is usually 5 to 15 seconds. It is especially suitable for the drying of heat sensitive raw materials.

2. Dried products have even granules, good flow ability and solubility.

3. Suitable and stable operation, easy adjustment and control as well as automation.

4. Simplifies the production process with its superior and sanitary operation environment. Also, flying dust can be avoided during the drying process.

Work Principle

The liquid raw material is fed into the drying tower by high pressure pump, where it is atomized into small droplets that are then mixed with hot air and moisture is evaporated. Most powder materials will be collected through the discharge port at the bottom of the drying machine's tower. Excess air and fine powder is separated through the cyclone separator. Material receiving rate can be up to 96-98%.

Technical Parameters

Model Selection| Model | 50 |

| Evaporated amount(kg/h) | 50 |

| d(mm)ΦxH | 1200x8900 |

| Power(KW) | 8.5 |

| Inlet air temperature(°C) | 300-350 |

| Water content (%) | <5(can reach to 0.5%) |

| Yield (%) | >97 |

| Heating by Electricity(KW) | 75 |

| Evaporation and Electricity(Mpa KW) | 0.5 54 |

| Furnace(Kcal/h) | 150000 |

| Model | 100 |

| Evaporated amount(kg/h) | 100 |

| d(mm)ΦxH | 1800x11500 |

| Power(KW) | 14 |

| Inlet air temperature(°C) | 300-350 |

| Water content (%) | <5(can reach to 0.5%) |

| Yield (%) | >97 |

| Heating by Electricity(KW) | 120 |

| Evaporation and Electricity(Mpa KW) | 0.6 90 |

| Furnace(Kcal/h) | 300000 |

| Model | 150 |

| Evaporated amount(kg/h) | 150 |

| d(mm)ΦxH | 2200x13500 |

| Power(KW) | 22 |

| Inlet air temperature(°C) | 300-350 |

| Water content (%) | <5(can reach to 0.5%) |

| Yield (%) | >97 |

| Heating by Electricity(KW) | |

| Evaporation and Electricity(Mpa KW) | 0.6 108 |

| Furnace(Kcal/h) | 300000 |

| Model | 200 |

| Evaporated amount(kg/h) | 200 |

| d(mm)ΦxH | 2400x14800 |

| Power(KW) | 24 |

| Inlet air temperature(°C) | 300-350 |

| Water content (%) | <5(can reach to 0.5%) |

| Yield (%) | >97 |

| Heating by Electricity(KW) | |

| Evaporation and Electricity(Mpa KW) | Temperature is below 200°C,calculating in accordance with pratical situation |

| Furnace(Kcal/h) | 400000 |

| Model | 300 |

| Evaporated amount(kg/h) | 300 |

| d(mm)ΦxH | 2800x15400 |

| Power(KW) | 30 |

| Inlet air temperature(°C) | 300-350 |

| Water content (%) | <5(can reach to 0.5%) |

| Yield (%) | >97 |

| Heating by Electricity(KW) | |

| Evaporation and Electricity(Mpa KW) | Temperature is below 200°C,calculating in accordance with pratical situation |

| Furnace(Kcal/h) | 600000 |

| Model | 500 |

| Evaporated amount(kg/h) | 500 |

| d(mm)ΦxH | 3400x18800 |

| Power(KW) | 40 |

| Inlet air temperature(°C) | 300-350 |

| Water content (%) | <5(can reach to 0.5%) |

| Yield (%) | >97 |

| Heating by Electricity(KW) | |

| Evaporation and Electricity(Mpa KW) | Temperature is below 200°C,calculating in accordance with pratical situation |

| Furnace(Kcal/h) | 1000000 |

| Model | 1000 |

| Evaporated amount(kg/h) | 1000 |

| d(mm)ΦxH | 4600x22500 |

| Power(KW) | 82 |

| Inlet air temperature(°C) | 300-350 |

| Water content (%) | <5(can reach to 0.5%) |

| Yield (%) | >97 |

| Heating by Electricity(KW) | |

| Evaporation and Electricity(Mpa KW) | Temperature is below 200°C,calculating in accordance with pratical situation |

| Furnace(Kcal/h) | 1500000 |