Dehumidifying Dryer

Request a Quote

SDD

Combined dehumidifying and drying system for processing plastic materials

Designed for the plastic processing industry, this dehumidifying and drying system is ideal for handling hygroscopic materials such as PET, PA, and PC. It can be strategically positioned either adjacent to injection molding machines for direct application or within a central material area to facilitate broader operational tasks. For volatile materials, incorporating an EOF oil filter is recommended to enhance safety and operational efficiency.

Features

- Features a comprehensive molecular sieve honeycomb rotor that consistently delivers stable, low-dew point air, avoiding the common problems associated with dual-tower dehumidifiers.

- The insulated drying hopper is engineered with a downward-blowing air bell mouth and cyclone exhaust, which improves drying efficiency and reduces heat loss, thereby saving energy.

- Includes a cooling component in the dehumidifying loop to maintain a low return air temperature and dew point for optimal drying conditions.

- Managed by a microcomputer control system that ensures temperature precision within ±1°C, enhancing process reliability.

- Equipped with a programmable weekly timer that automates the system's operations, optimizing efficiency and reducing operational workload.

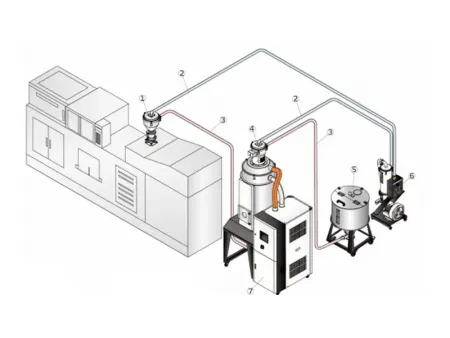

Components

- Hopper with photoelectric sensor

- Vacuum pipe

- Material pipe

- Vacuum hopper

- Material storage tank

- Separator vacuum loader

- SDD combined dehumidifying and drying system

Specifications

| Model SDD- | Regeneration heater power (kW) | Regeneration blower power (kW) | Drying heater power (kW) | Drying blower power (kW) | Drying air volume (m³/hr) | Insulated hopper (L) | Dimensions (mm) H×W×D | Weight (kg) |

| 3 | 0.12 | 4 | 0.18 | 40 | 40 | 1509×978×931 | 165 | |

| 3 | 0.12 | 4 | 0.18 | 40 | 80 | 1796×1060×1030 | 190 | |

| 3 | 0.18 | 4 | 0.75 | 80 | 120 | 1817×1061×893 | 250 | |

| 3 | 0.18 | 4 | 0.75 | 120 | 160 | 1740×1220×855 | 255 | |

| 4 | 0.18 | 6 | 0.75 | 120 | 160 | 2070×1061×893 | 265 | |

| 4 | 0.18 | 6 | 0.75 | 120 | 230 | 2052×1210×893 | 295 | |

| 4 | 0.4 | 12 | 1.5 | 200 | 300 | 2040×1450×1050 | 420 | |

| 4 | 0.4 | 12 | 1.5 | 200 | 450 | 2440×1450×1050 | 550 | |

| 7.2 | 0.75 | 18 | 3.75 | 400 | 600 | 2380×1745×1255 | 620 | |

| 7.2 | 0.75 | 18 | 3.75 | 400 | 750 | 2610×1745×1255 | 650 | |

| 10 | 1.5 | 24 | 7.5 | 700 | 900 | 2640×2140×1380 | 830 | |

| 10 | 1.5 | 24 | 7.5 | 700 | 1200 | 3070×2140×1380 | 870 | |

| Notes: 1) Plastic materials can be fully dried by drying air with dew-point temperature ≤-20°C 2) Power: 3Φ, 400VAC, 50Hz | ||||||||