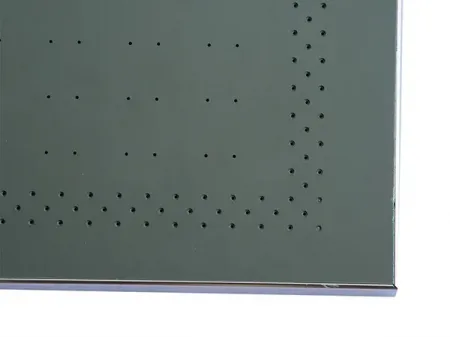

Heated Vacuum Table

Vacuum Workholding Solution

Available in various sizes and configurations based on client requirements

Our heated vacuum table integrates precise temperature control with reliable suction capabilities. The heat it distributed uniformly throughout the tabletop offering a versatile solution for various material process where a thermal bond is needed.

- Adaptability for various processing methods Our heated vacuum tables can be used in conjunction with various processing equipment, including laser cutting machines, CNC machining centers, UV printers, and more, making them highly versatile across different industries.

- Temperature control The vacuum table comes with a built-in heating function, allowing temperature adjustments according to material properties and processing requirements. This feature helps to soften materials, improve processing efficiency, and prevent material deformation or damage caused by temperature fluctuations.

- Customization services We offer customized heated vacuum tables, designing the table’s size, suction power, heating temperature, and other parameters based on your specific needs to ensure optimal performance.

- Improved processing precision With a flatness precision of up to 0.10mm, our heated vacuum tables ensure that materials are securely held in place with high stability, minimizing errors and deformation during processing.

Our heated vacuum tables are ideal for material handling in various kinds of precision applications. They provide stable and secure hold-down, ensuring accurate positioning during processes such as biological experiments, 3D printing, laboratory tasks, and more. With their precise temperature control, they prevent material deformation and improve processing efficiency across different applications.

- Customized vacuum hold-down tables:

We design and manufacture customized vacuum tables based on the specific needs of our clients. These vacuum tables can accommodate materials of various sizes, shapes, and types, ensuring stability and precision during the printing process. The optimal flatness of our vacuum tables can even reach 0.10mm, guaranteeing high-quality results.

- Comprehensive solutions:

We provide full vacuum work-holding solutions for the printing industry, including technical support and consultation services. Our solutions address material hold-down, surface flattening, and improved printing precision, helping customers overcome common challenges and improve overall production efficiency.

- Technical support and product design:

We offer technical support and training services to help customers understand and effectively use their vacuum tables. You can contact our sales team to discuss your requirements and budget. With our deep industry expertise, we'll work closely with you to craft a tailored solution, ensuring the best possible outcome for your project. We provide flexible customization, with the ability to manufacture vacuum tables up to 4000mm x 2100mm (larger sizes available upon request).

- Continuous research and innovation:

We are committed to research and innovation, holding over 50 patents and continually introducing new technologies and products to meet the evolving needs of the printing industry. Through collaborations with research institutions such as Sun Yat-sen University and South China University of Technology, we’ve made significant technological advancements in the vacuum hold-down table industry, enhancing both product performance and market competitiveness.

- After-sales support:

We offer comprehensive after-sales service, with a dedicated support team that responds quickly to customer needs, ensuring customer satisfaction at every stage.

- Email:

- Mobile:

Need assistance with vacuum tables? Contact our team for expert guidance!