Cutting Machine Vacuum Table

Vacuum Workholding Solution

Available in various sizes and configurations based on client requirements

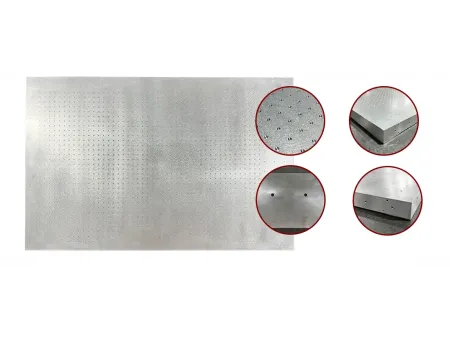

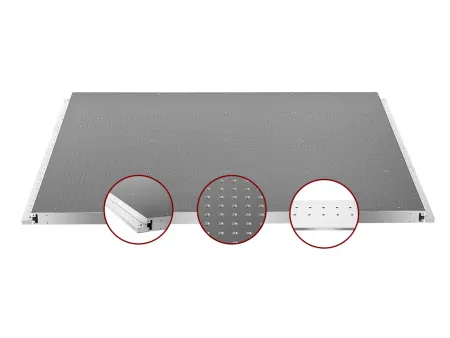

Our cutting machine vacuum tables are designed for a wide range of materials, including metals, non-metals, and flexible materials, meeting the diverse needs of different industries. We offer customizable vacuum tables to meet specific customer requirements, including surface size, vacuum hole diameter and spacing, suction area, and suction hole diameter, ensuring optimal performance for various materials and cutting processes.

Constructed with lightweight aluminum honeycomb core materials, our vacuum tables provide excellent strength, rigidity, and stability during cutting, ensuring durability. The flatness of the table can achieve a precision of up to 0.15mm, made possible by advanced manufacturing techniques and testing equipment, guaranteeing a flat and flawless surface suitable for high-precision applications. We also offer personalized non-standard customization services, working closely with clients from design to production to ensure the final product meets both functional and specific customization needs.

- Increased cutting precision and efficiency

Precise positioning: The vacuum hold-down system ensures materials stay securely in place, greatly enhancing cutting accuracy.

Simplified operations: Optimized design and advanced suction technology reduce operational complexity, making the cutting process more automated and intelligent, boosting efficiency.

- Enhanced material compatibility

Wide applicability: Our cutting machine vacuum tables support a variety of materials, including metal, non-metal, and flexible materials, catering to diverse cutting needs.

Custom solutions: We offer tailored vacuum tables based on customer requirements, including surface size, vacuum hole diameter, spacing, and suction area to match specific materials and cutting processes.

- Optimized equipment performance and stability

Lightweight yet strong: The aluminum honeycomb core provides excellent strength, rigidity, and stability, ensuring durability during cutting operations.

Uniform suction power: The optimized design guarantees uniform suction across the entire table, eliminating quality issues caused by uneven suction.

- Enhanced safety and environmental benefits

Safety features: The vacuum table ensures stable suction and structural integrity, creating a safe working environment for operators during the cutting process.

Energy efficient and eco-friendly: The vacuum table operates with low noise and minimal energy consumption, meeting modern industrial requirements for sustainability.

- Reduced costs for production and maintenance

Improved Efficiency: Higher cutting accuracy and efficiency help minimize material waste and rework, reducing overall production costs.

Low Maintenance Costs: With a well-designed structure, the tabletop is easy to clean and maintain, further reducing operational costs.

Our vacuum tables can be fully customized to meet specific customer requirements. Whether it’s the surface size and dimensions, vacuum hole diameter and spacing, suction area, suction hole diameter, number of suction holes, connection methods, or custom zones for independent suction or non-suction areas, we offer tailored solutions.

We are backed by a professional technical team that provides comprehensive support and consultation services. Whether customers face challenges during operation or need technical assistance, our team is ready to respond promptly with effective solutions.

For first-time users of vacuum tables, we offer training and guidance services, including operation training, maintenance and upkeep training, and troubleshooting. Through these training programs, customers gain a deeper understanding of the vacuum table’s performance, learn the correct operating methods, and acquire maintenance skills, ultimately improving both production efficiency and product quality.

- Email:

- Mobile:

Need assistance with vacuum tables? Contact our team for expert guidance!