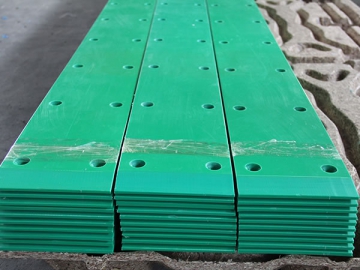

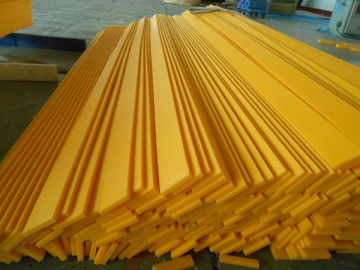

UHMWPE Wear Strip

UHMWPE wear stripis one of the most popular selections of plastic wear strip, because of Ultra High Molecular Weight Polyethylene's low coefficient of friction, noiselessness, and smooth operation.

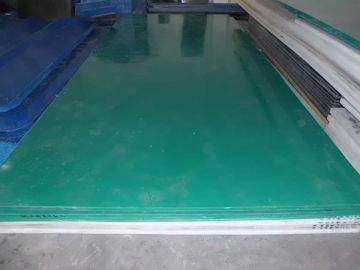

As a custom plastic fabrication solutions provider, we can supply UHMWPE wear strips with customized sizes.

Main Advantages of UHMWPE Wear Strips

1. High chemical resistance, fatigue resistance, noise dampening, radiation resistance.

2. High end temperature range: 100-110℃

3. The wear strip fabricated from engineering plastic has outstanding impact resistance, resistance to stress cracking, low coefficient of friction, and self-lubrication.

4. Structurally sound down to -269℃.

5. Density: 0.985g/cm3

6. Molecular weight of 2,000,000

7. Tensile strength: 40MPa

8. Crack elongation: 350%

9. Elastic modulus: 600MPa tortuous Izod notched impact punch continued.

10. Amount of wear (MPC method): 20mm.

Applications of UHMWPE Wear Strips

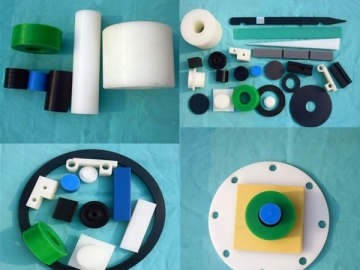

Our UHMWPE wear strips can be widely used for long-term maintenance-free purposes. This UHMWPE profile can be applied to office equipment, textile machinery, pneumatic components, fitness equipment, printing machinery, micro-motors, automobiles, agricultural machinery, cement grout pumps, port machinery, and other applications that require corrosion-resistant sliding parts.

Related Names

UHMWPE Wear Strip | PE Wear Strip | UPE Wear Strip | PE 1000 Wear Strip | PE 500 Wear Strip