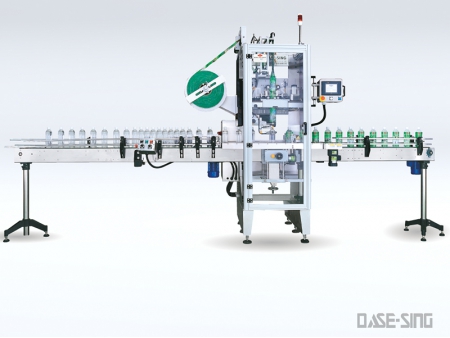

DSV-200P2 Single Head Shrink Sleeve Labeling Machine

Automatic shrink sleeve label applicator for speeds up to 200BPM

DSV-200P2 shrink sleeve labeling machine is a single-head shrink sleeve label applicator with a standard speed of 200 BPM/180mm (standard length). It features a specially designed knife plate that allows for label application within the rated specifications without the need for replacement, and rapid replacement under specific conditions. Due to its compact and streamlined design, this labeling equipment is suitable for medium production volumes and is ideal for food manufacturers or flexible packaging companies with limited factory space.

- Maximum Speed: 200 BPM

- Bottle Outer Diameter: Ø25mm to Ø125mm (based on customer-provided bottle specifications)

- Film Material: PVC / PET / OPS

- Film Thickness: PVC: 0.035mm to 0.08mm, PET: 0.04mm to 0.06mm, OPS: 0.04mm to 0.06mm

- Machine Dimensions (L×W×H): 1403mm×960mm×2090mm (our company reserves the right to modify the machine's dimensions for equipment optimization)

- Voltage: 220V

- Compatible Containers: Supports a wide range of container shapes, including round, oval, square, and more.

- Can be fully integrated with production and packaging lines.

- Equipped with protective covers and a color human-machine interface (HMI) for parameter configuration, making it easier to manage production lines.

- Unique knife plate design eliminates the need for changing knife plate within the specified range. If replacement is necessary, it can be done quickly within minutes.

- Integrated design is provided for easy adjustment of the entire machine's transmission mechanism when handling labels of various specifications.

- Allows for continuous adjustment within a paper core inner diameter of 5" to 10".

- Utilizes PLC control to enhance labeling accuracy and speed.

- Streamlined design for easy installation, occupying minimal floor space, providing flexibility in space utilization.

- If additional labeling capacity is required, the main machine part can be purchased separately (excluding timing screw for bottle feeding and other equipment) and placed downstream of the existing labeling machine, significantly reducing the distance between labeling machines and showcasing space-saving advantages.

- For labeling same type of bottles, it can be connected in series with 2 or 3 labeling machines to achieve simultaneous labeling of bottle bodies and caps. If choosing the mode for labeling only bottle body without cap, it can provide higher production output. Different film materials can be placed for various packaging needs to enhance production efficiency.

- Optional perforation mechanism for easy removal of plastic labels by consumers.

- Neck Tamper Evident Banding Used for sealing bottle necks, preventing tampering, and maintaining product integrity.

- Full Body Over-The-Cap Sleeve Labeling Labels cover the bottle neck, body, and bottom, commonly used for sauces, condiments, and similar products.

- Full Body Shrink Sleeve Labeling Labels cover from the lower edge of the bottle neck to the bottom, commonly used for juices, coffee, and more.

- Partial Body Shrink Sleeve Labeling Labels are positioned in the center of the bottle body, commonly used for various bottled and canned products.

- Full Body & Underlap Sleeve Labeling Designed for products requiring labeling to the bottom, enhancing product aesthetics and presentation.

Our shrink sleeve labeling machine finds extensive applications in various packaging industries, including beverage packaging, dairy packaging, bottled water packaging, pharmaceutical packaging, personal care packaging, and more. It is suitable for bottles or containers of different sizes and shapes, including square, curved, cup-shaped, and unique types of containers.