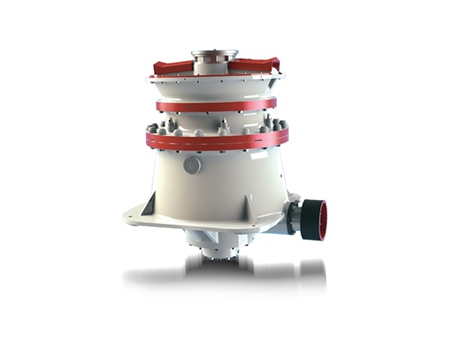

Cone Crusher, DHP Series

Stone Crushing Machine, Rock Crushing Machine, Ore Crusher, Hydraulic Crushing Machine, Hydro Cone Crusher

DHP series hydraulic cone crusher breakthroughs the traditional cone crusher design and utilizes the laminated crushing principle to improve its crushing capacity and quality. The supplementary lubricating system not only ensures the reliable running of the cone crusher, but also helps to save the time and labor costs considerably.

Features of the hydraulic cone crusher

1. High efficiency

With an intelligent design, the crushing procedure is displayed digitally and intuitively, enabling a convenient adjustment. The working process is controlled by program and the oil pressure is adjusted automatically. An alarming device is adopted. With the cone dimension being the same, the hydraulic cone crusher allows for an increase of 35%-60% output and a decrease of 20% power consumption comparing with the spring cone crusher.

2. Multi-purpose & easy-controlled

By readjusting the position of accessories and replacing some consumable parts, the crushing machines can be classified into 3 chamber types. When there is a machine failure, it is unnecessary to disassemble the crusher since the hydraulic system will let the system discharge the materials in the chamber automatically.

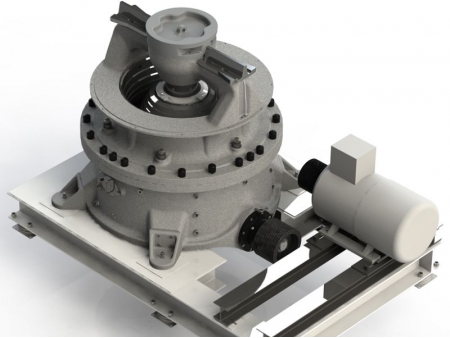

3. Lubricating system & overload protection mechanism

Equipped with an oil lubrication system, the spare parts of the hydro cone crusher are able to run smoothly. The hydraulic control system effectively guarantees the overload protection mechanism of the machinery.

4. Easy operation

The hydraulic control system contributes to an automatic adjustment process, simplifying the operation largely.

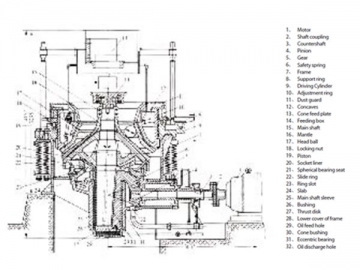

Working principle of the crusher

When the cone crusher is running, the transmission shaft and the cone will perform rotary motion around a fixed axis under the pressure of the eccentric sleeve, which is motivated by the motor. In this way, the crushing wall will sometimes approach the rolling acetabular wall which is attached to the adjusting sleeve and sometimes leave it. Then the ores will be impacted, pressed, and bent constantly and finally get crushed.

Applications of the hydraulic crusher

The DHP series hydraulic cone crusher is widely used for crushing ore, high-hardness rock, building materials and other products in cement, and sand making industries, etc.

| Model | Max feeding size (mm) | Min size of discharge opening (mm) | Rotating speed (r/min) | Motor power (kw) | Production capacity (TPH) Closed-side setting (mm) | |||||

| 19 | 22 | 25 | 38 | 45 | 51 | |||||

| DHP-C4013 | 180 | 19 | 750 | 110~150 | 175~215 | 195~245 | 260~315 | |||

| DHP-F4013 | 140 | 17 | 750 | 110~150 | 140~170 | 155~200 | 180~225 | 225~285 | ||

| DHP-C4318 | 200 | 22 | 750 | 180-225 | 205~245 | 225~285 | 285~355 | 315~385 | 355~435 | |

| DHP-F4318 | 185 | 19 | 750 | 180~225 | 185~225 | 200~235 | 220~255 | 265~335 | ||

| DHP-C4522 | 280 | 25 | 750 | 220~300 | 290~360 | 365~485 | 425~505 | 465~555 | ||

| DHP-F4522 | 205 | 22 | 750 | 220~300 | 260~315 | 285~335 | 345~415 | 385~445 | ||

| DHP-C4825 | 350 | 27 | 750 | 250~315 | 345~435 | 435~555 | 515~615 | |||

| DHP-F4825 | 240 | 25 | 750 | 250~315 | 315~385 | 345~420 | 415~505 | 445~535 | 555~665 | |