Cone Crusher, DSC Series

Stone Crusher, Gravel Crushing Machine, Ore Crusher, Hydraulic Cone Crusher, Sand Making Machine

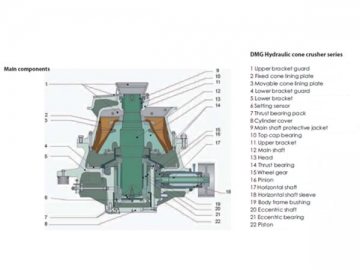

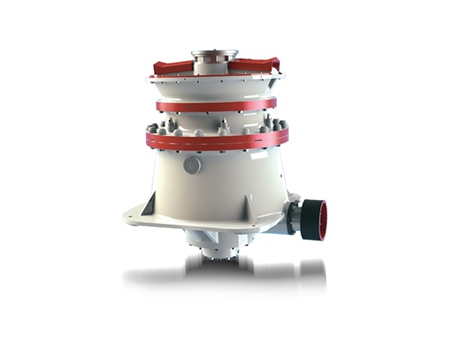

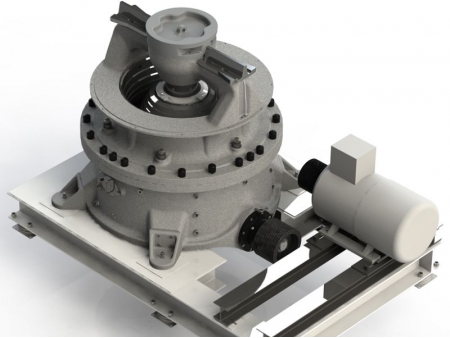

The single cylinder hydraulic cone crusher with hydraulic power system is a new type of highly-efficient crushing equipment. It is widely used in secondary crushing, tertiary crushing and fine crushing process, with the ability of crushing ores and rocks with different even the highest hardness.

Dongmeng hydraulic cone crusher features compact structure. Three important functions which are respectively discharge opening adjustment, overload protection and cavity cleaning are realized with the unique single-cylinder design. So, we didn' t additionally set an adjustment device for the opening, or a hydraulic cylinder or spring for overload protection. The whole crusher structure is rather compact and simple.

Features of the single cylinder hydraulic cone crusher

1. High efficiency

Having supports both for the upper and lower ends of the main shaft, the stone crushing machine can bear large crushing force and stroke. The specially-designed cavity which employs lamination principle endows the crusher with large crushing efficiency.

2. Large production capacity

With a perfect combination of crushing stroke, speed, and cavity shape, the hydraulic cone crusher allows for 35%-60% of more output than the traditional spring cone crusher which shares the same cone diameter with the hydraulic type.

3. Uniform crushing result

With the unique crushing chamber and laminated crushing principle, a crushing effect will be generated among the particles. So, there will be more cube type and less acicular or sheet shapes gravel particles.

4. Convenient conversion for crushing process

It only needs to change the cone to realize a conversion between the secondary and fine crushing.

5. Overload protection & good lubricating effect

Hydraulic device and lubrication system are adopted to ensure the overload protection and lubricating effect.

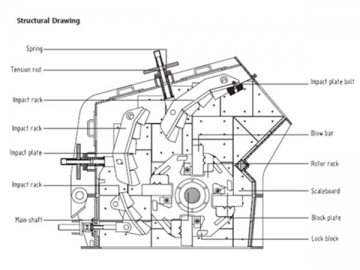

Working principles of the hydraulic cone crusher

The crushing process of the cone crusher machine is finished between the fixed cone plate and the movable cone plate. With the motor driving the horizontal axis of the crusher machine through triangle belt and pulley, the eccentric shaft bush is able to rotate through gear transmission. Then the main shaft will be motivated to make the movable cone plate swing along a predetermined track periodically, the materials are crushed due to the constant pressure in the crushing cavity. Finally, the finished products are discharged from the discharging opening.

Applications of the cone stone crusher

Single cylinder hydraulic cone crushers are divided into standard and short-head types, the 2 kinds of which are applied separately in secondary and fine crushing projects. Hydraulic cone crusher with single cylinder is widely used for crushing ores or rocks of high hardness and wear resistance in metallurgy, construction, road, chemical, and building material industries. It is especially suitable for crushing metal ores, and sand & gravel materials for construction uses.

| Model | Max motor power (kw) | Max feeding size (mm) | Processing capacity under min discharge opening condition (t/h) | |||||||||||||

| 19 | 25 | 29 | 32 | 35 | 38 | 41 | 44 | 48 | 51 | 54 | 60 | 64 | ||||

| DCS160 | 132-160 | EC | 360 | 126 | 138-173 | 147-230 | 156-293 | 165-310 | 174-327 | 183-344 | 196-306 | 205-256 | 214 | |||

| C | 300 | 116-145 | 127-199 | 135-254 | 144-270 | 152-285 | 161-301 | 169-264 | 180 | |||||||

| MC | 235 | 91 | 106-166 | 116-218 | 124-232 | 131-246 | 139-261 | 147-275 | 154-241 | 165 | ||||||

| DCS250 | 220-250 | EC | 450 | 267 | 282-353 | 298-448 | 313-563 | 334-601 | 349-524 | 365-456 | ||||||

| C | 400 | 225 | 239-299 | 254-381 | 269-484 | 284-511 | 298-448 | 318-398 | 333 | |||||||

| MC | 300 | 195 | 214-267 | 228-342 | 242-435 | 256-461 | 270-486 | 284-426 | 303-378 | 317 | ||||||

| DCS315 | 280-315 | EC | 560 | 349 | 368-460 | 392-588 | 410-718 | 428-856 | 465-929 | 489-978 | ||||||

| C | 500 | 318 | 336-420 | 353-618 | 376-753 | 394-788 | 411-823 | 446-892 | 469-822 | |||||||

| Model | Max motor power (kw) | Max feeding size (mm) | Processing capacity under min discharge opening condition (t/h) | |||||||||||||

| 6 | 8 | 10 | 13 | 16 | 19 | 22 | 25 | 32 | 38 | 44 | 51 | |||||

| DCH160 | 132-160 | EC | 185 | 69-108 | 75-150 | 80-161 | 86-171 | 91-182 | 104-208 | 115-208 | ||||||

| C | 145 | 66-131 | 71-142 | 76-152 | 81-162 | 86-173 | 98-197 | 109-150 | ||||||||

| MC | 115 | 57 | 62-140 | 67-151 | 72-162 | 77-173 | 82-184 | 93-145 | ||||||||

| M | 90 | 64-84 | 69-131 | 75-142 | 80-152 | 86-162 | 91-154 | 104 | ||||||||

| MF | 75 | 61 | 65-106 | 70-115 | 76-124 | 81-126 | 87-114 | 92 | ||||||||

| F | 50 | 48-78 | 51-83 | 54-88 | 59-96 | 63-103 | 68-105 | 72-95 | 77 | |||||||

| EF | 35 | 70-90 with 80%finer than 5.5-5.6mm | ||||||||||||||

| DCH250 | 220-250 | EC | 215 | 114-200 | 122-276 | 131-294 | 139-313 | 159-357 | 175-395 | 192-384 | ||||||

| C | 175 | 101 | 109-218 | 117-292 | 125-312 | 133-332 | 151-378 | 167-335 | 183-229 | |||||||

| MC | 140 | 97-122 | 105-262 | 113-282 | 120-301 | 128-320 | 146-328 | 161-242 | ||||||||

| M | 110 | 117-187 | 126-278 | 136-298 | 145-318 | 154-339 | 176-281 | 194 | ||||||||

| MF | 85 | 114 | 124-227 | 134-245 | 144-263 | 153-281 | 163-299 | 186-248 | ||||||||

| F | 70 | 90-135 | 96-176 | 104-191 | 112-206 | 120-221 | 129-236 | 137-251 | 156-208 | |||||||

| EF | 38 | 100-125 with 80%finer than 6-7.5mm | ||||||||||||||

| DCH315 | 280-315 | EC | 275 | 177 | 190-338 | 203-436 | 216-464 | 246-547 | 272-605 | 298-662 | 328-511 | |||||

| CX | 245 | 174-194 | 187-374 | 200-488 | 212-510 | 242-582 | 268-654 | 293-521 | 323-359 | |||||||

| C | 215 | 171-190 | 184-367 | 196-480 | 209-510 | 238-582 | 263-643 | 288-512 | 317-353 | |||||||

| MC | 175 | 162-253 | 174-426 | 186-455 | 198-484 | 226-502 | 249-499 | 273-364 | ||||||||

| M | 135 | 197-295 | 211-440 | 226-470 | 240-500 | 274-502 | 302-403 | |||||||||

| MF | 115 | 192 | 207-369 | 222-396 | 237-423 | 252-450 | 287-451 | 318-363 | ||||||||

| F | 85 | 195-304 | 210-328 | 225-352 | 241-376 | 256-400 | 292-401 | 323 | ||||||||

| EF | 65 | 211-293 | 227-316 | 244-298 | 261-290 | |||||||||||