Conical Steel Drum Making Machine

Founded in 2000, Bohai is consistently providing our customers with our top-quality steel drum production lines. Dedicated to the research and development, the quality improvement and cost reduction of steel barrel production lines, Bohai always places its priority to steel drum manufacturing enterprises’ demands. In order to meet the requirements of different drum making enterprises, Bohai has developed metal steel drum production lines of different capacities, including high speed steel drum manufacturing equipment, middle speed automatic steel drum production lines, and low speed metal packaging drum production lines. Our steel barrel production lines can manufacture the following drums, such as steel conical barrel, closed head 55 gallon drum, open head steel barrel, and bituminous steel barrel.

The inner diameter of the opening and bottom of a metal conical barrel is not the same. Conical barrel’s production is mainly processed by the conical steel drums expanding machine. Due to the shape of conical packing drums, empty conical drums can be stacked, improving space utilization and reducing transportation costs. A 40HQ container can hold at least 2000 finished open conical drums, in favor of long-distance transportation and export of goods. Therefore, compared to traditional steel barrel production enterprises, conical barrel production enterprises have a bigger area of sales.

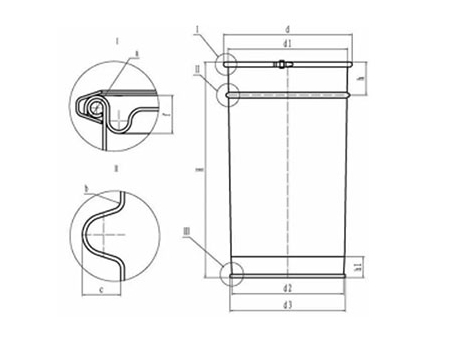

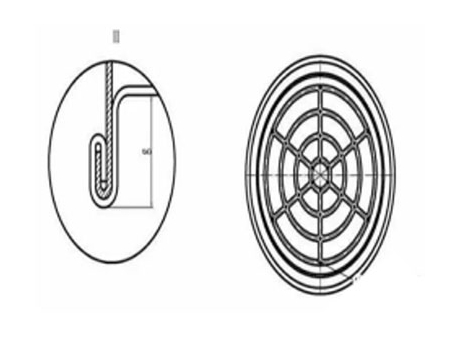

Commonly used colored conical barrels are of 200L and 215L, and are mainly designed for tomato ketchup production companies. The thickness of conical barrel bodies is 0.6-0.7mm, and the thickness of barrel’s top cover and bottom is 0.8mm. The thickness of locking ring is 1.2mm and of cap seal is 1.0mm. When compared with closed head steel barrel and open head steel barrel, steel conical drum has a more complicated opening structure, whose main purpose is to prevent rainwater accumulation.

Conical steel barrel production line consists of dozens of processes, from uncoiling, cutting to barrel forming, coating, baking and other processes. Conical steel barrel production line covers an area of about 2500 square meters, with a stacking area of about 500 square meters. This steel barrel production line requires 2-10 employees. Bohai serves our customers technical assistance and rational equipment layout, thus to avoid the waste of workplace.

Bohai provides custom conical steel barrel making equipment for metal drum companies.

1. Bohai offers parts of conical steel barrels, including drum body sheet, drum top cover, drum bottom, steel drum hoops and etc. Barrel making enterprises only require conical drum forming equipment and conical drums expanding machine to process semi-finished products, which highly saves the initial investment. Besides, due to its feature of easy transportation, finished conical steel barrels can be delivered directly to our clients.

- Drum Top Cover

- Drum Bottom

- Drum Bung

- Steel Drum Hoop

- Drum Body Sheet

2. Conical steel barrel production line uses ordinary 50-2201 steel drum production line and conical drum expanding machine together. Therefore, when possessing conical clean steel drum production line, drum making enterprises can produce both conical steel drums and 55 gallon metal drums. When equipped with moulds, and owning reasonable layout of steel drum production line, our clients can enjoy many types of steel drum manufacturing line including closed drums, bituminous asphalt steel drums, open top steel drums and conical steel barrel.

- Closed Head Drum

- Open Head Drum

- Bituminous Drum

- Conical Drum

3. Conical steel drum production line takes commonly used 50-220l steel drum making machinery as its basis. Bohai can serve 55 gallon steel drum making machinery of high, middle and low speed in accordance with the manufacturing requirements of barrel making enterprises. Low speed steel drum production line requires labor involvement, while it needs minimum investment cost and land input. Middle speed steel drum production line can produce 5 drums per minute, and is the best-selling steel barrel making line at present. High speed barrel making machine line is fully automatically controlled, and capable of producing 8 drums per minute.

Flash rust of paint film on the surface of steel drums always occurs in the drying process of paint film, and its emerging is always due to dissolution and precipitation of iron compounds.

- Accelerate Drying Process: High temperature and low humidity expedite the drying process of paint film. The reasonable operating temperature of steel barrel production line is 10-35 ℃, with a relative humidity of 40%-70%. At the same time, the surface temperature of the steel barrel should be 3 ℃ higher than the dew point temperature. When the steel barrel production line is running, on-site ventilation should be improved to facilitate the evaporation of moisture and promote the drying of the steel barrel paint film.

- Paint Film Thickness: Thick paint film leads to a highly slackened water evaporation. Therefore, the thicker the paint film, the easier it is to produce flash rust. When thicker paint film is required for some steel drums, some coalescing agents can be added to improve water evaporation rate on the surface of the steel drum.

- Avoid Contamination of Metal Raw Materials: When steel drum production lines are in operation, choose steel drum raw materials that are not prone to flash rust, and clean the oil, impurities, and other impurities in the steel drum raw materials.

- Use Flash Rust Inhibitors: When steel barrel production line is running, a reasonable usage of flash rust inhibitor can effectively prevent the occurrence of flash rust.