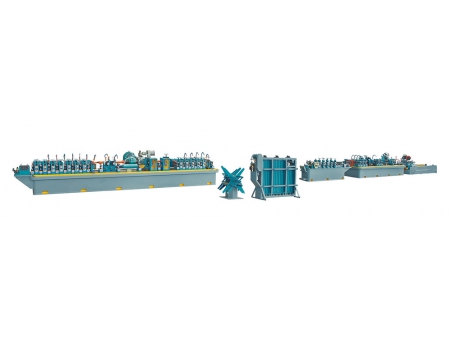

BH50 High-Frequency Pipe Making Machine

Established in 2000, Bohai is a professional automatic flexible forming tube mill line manufacturer. Bohai endeavors to the research & development, and manufacturing of stainless steel tube mill line of different series, and offers steel pipe making manufacturing enterprises with professional after-sales service and technical assistance.

BH50 Series automatic flexible pipe forming machine mainly produce welded pipes with the diameter ranging from Ø15~Ø76mm and the wall thickness ranging from 0.7~2.5mm, as well as square tubes, rectangular pipes and special-shaped pipes of same dimensions. With rolling forming design, welded pipes can be produced with high processing quality and assembly precision.

| Item | Working Range |

| Outer diameter. | Ø15mm~Ø76mm |

| Pipe thickness. | δ0.7mm~2.5mm |

| Square tube size | 12×12mm~60×60mm |

| Square tube thickness | δ0.7mm~2.0mm |

| Rectangular pipe size | 10*15mm~40×80mm |

| Rectangular pipe thickness | δ0.7mm~2.0mm |

| Produce speed | 20M/min~100M/min |

| Pipe length | 4M~8M |

| Item | Working Range | Remark |

| Thickness of strips | δ0.7~2.5mm | Material: low-carbon steel, low alloy steel strip(δs ≤ 980MPa, δb ≤ 345MPa) |

| Width of strips | 47~240mm | |

| O.D. of steel coil | Ø800mm~Ø1600mm | |

| I..D. of steel coil | Ø450mm~Ø550mm | |

| Maxi. Load weight | ≤2500kgs |

Raw material (steel coil) → uncoiling →material accumulating → forced leveling →mill-forming → high-frequency welding → removing burrs outside of weld seam → cooling → sizing → roughly straightening → fixed length cutting → run-out table

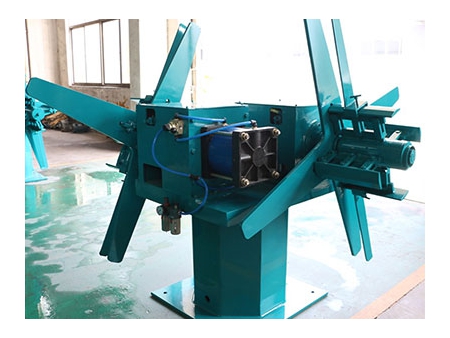

- Pneumatic double-side uncoiler

- Shear and Butt-Welder

- Vertical Accumulator for Tube Mill

- Forming Welding Sizing Machine

- Sizing Machine

- Computer-Controlled Cutting Saw

- Run-Out Table

- Rollers

Flash rust of paint film on the surface of steel drums always occurs in the drying process of paint film, and its emerging is always due to dissolution and precipitation of iron compounds.

- Adjusting welding speed: Adjust the welding speed of the tube mill machine based on the pipe diameter and wall thickness. Excessive speed of the automatic flexible ERW tube mill line is prone to welding fracture, and low speed may cause welding unevenness. Therefore, when adjusting the speed, focusing on the operating status of the pipe forming machine and prompt reaction are required and appropriate measures should be taken to avoid the wrong speed.

- Adjusting Current and Voltage: The current and voltage are determined by the pipe diameter and wall thickness. Generally speaking, the larger the pipe diameter and the thicker the wall thickness, higher current and voltage should be to ensure the quality of welding. When adjusting the current and voltage, attention should be paid to the safety and quality of the automatic flexible pipe forming machine, and appropriate measures should be taken to ensure the smooth progress of welding.

- Adjusting Pipe Diameter: Different pipe diameters require different pipe clamps for fixing. When adjusting the pipe diameter, attention should be paid to the stability and the quality of the high efficiency pipe making machine, and appropriate measures should be taken to avoid problems such as pipe sliding or misalignment.

- Adjusting the Angle: Adjust the pressure and speed of the pipe making machine tube mill according to the inclination angle and bending degree of the pipeline to ensure the quality and stability of welding. When adjusting the angle, attention should be paid to the quality of vulnerable parts and tube making machine, and appropriate measures should be taken to ensure the reliability and safety of the operation.