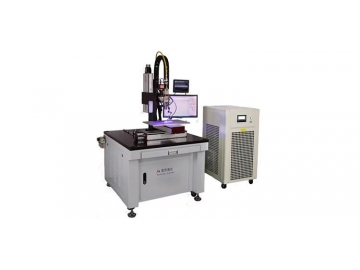

Precision Fiber Laser Welding Machine

- Weldable material: The weldable material is metal equivalent material (all kinds of carbon steel, stainless steel, aluminum alloy, gold, silver, precious metals, etc.), and also can be dissimilar metals (copper to steel, copper to titanium, nickel to titanium, etc.).

- Mainly used for welding of same materials such as stainless steel, gold, silver, iron, aluminum, alloy, steel and diamond or welding of dissimilar materials. Widely used in sensors, mobile phone batteries, high-end bathroom products, medical equipment, craft gifts, watches, electronic components, precision machinery, electronic communications and other industries.

- Optical fiber cantilever mold laser welding machine is equipped with optical fiber transmission system, that is different than the standard cantilever laser mold welding machine. Adopt non-workbench operation mode, through optical fiber transmission to achieve precision repair for super large, large and medium-sized molds.

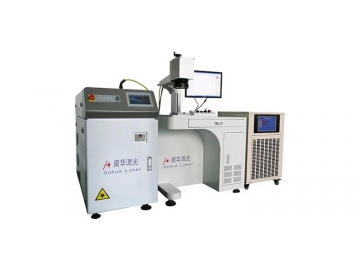

Precision Fiber Laser Welding Machine

Precision Fiber Laser Welding Machine Application

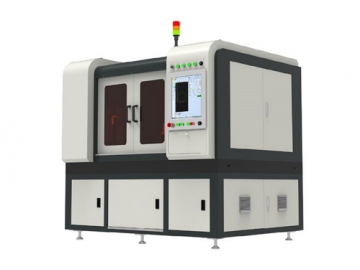

Application

Application

The precision fiber laser welding machine is used in the welding of optical communication devices, medical equipment, batteries, optical fiber coupling devices, metal parts, mobile phone vibration motors, precision clock components, and automotive steel.

| Model | | | | |

| Item | Parameter | Value | Value | Value |

| Laser machine parameter | Maximum laser output power | 200W | 400W | 600W |

| Maximum laser peak power | 12KW | 12KW | 12KW | |

| Laser wavelength | 1064nm | 1064nm | 1064nm | |

| Maximum laser pulse energy | 90J/10ms | 110J/10ms | 130J/10ms | |

| Pulse width | 0.2-20ms | 0.2-20ms | 0.2-20ms | |

| Laser pulse frequency | 1-40Hz | 1-40Hz | 1-40Hz | |

| Fiber parameter | Fiber inner diameter | 0.6mm | 0.6mm | 0.6mm |

| Fiber length | 3/5/10/12 m | 3/5/10/12 m | 3/5/10/12 | |

| Spectral energy error | < 1% | < 1% | < 1% | |

| Light spot size | 0.2mm - 1.5mm | 0.2mm - 1.5mm | 0.2mm - 1.5mm | |

| Welding depth | 0.1mm – 1.2mm | 0.1mm – 1.6mm | 0.1mm – 1.6mm | |

| Aiming location | Red light instrument & CCD image amplifying and monitoring system | Red light instrument & CCD image amplifying and monitoring system | Red light instrument & CCD image amplifying and monitoring system | |

| Motivate speed | ≤200mm/s | ≤200mm/s | ≤200mm/s | |

| Physical feature and others | Power consumption | ≤9KW | ≤12KW | ≤15KW |

| Cooling system | Integrated forced water chiller | Integrated forced water chiller | Integrated forced water chiller | |

| Power requirement | Three phase220V±5%, 50Hz, 60A | Three phase380V±5%, 50Hz, 60A | Three phase380V±5%, 50Hz, 60A | |

| Installation area | 1.5mx2m | 1.5mx2m | 1.5mx2m | |

| Using environment | No dust, no vibration source, 13℃-28℃, humidity 5%-75% | No dust, no vibration source , 13℃-28℃, humidity 5%-75% | No dust, no vibration source, 13℃-28℃, humidity 5%-75% | |

| Supplies | xenon lamp, filter element, protective lens, argon, water, electricity | xenon lamp, filter element, protective lens, argon, water, electricity | xenon lamp, filter element, protective lens, argon, water, electricity | |

| Optional fittings | anti-laser glasses | anti-laser glasses | anti-laser glasses | |

Features

● Under average welding light spot energy, the precision fiber laser welding machine will provide excellent light positioning.

● It can be used to weld all kinds of complicated welding seams.

● The machine adopts a British ceramic spotlight chamber, making it more durable and temperature resistant. Manually welding is convenient for 3m fibers, 5m fibers.

● For easy observation and location precision, a CCD camera monitoring system is optional.

● To realize mass production, you can customize the automatic chemical fixture.

Principle

The precision fiber laser welding machine is usually used to spot weld large molds and electronic components. After passing fiber and collimating lenses, the laser will be parallel, and then according to manually focusing, the laser will work on any objects.