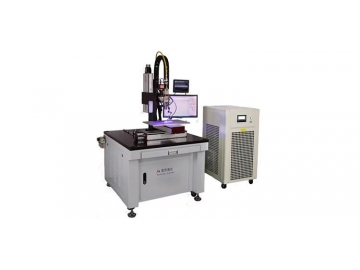

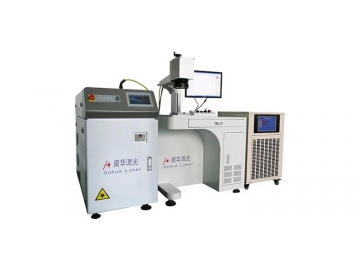

Continuous Fiber Optic Laser Welding Machine, AHL-FL1000 Laser Welder

Application

The high power fiber laser welding machine is used in the welding process of gears, bearings, door handles, kettles, faucets, roof components, metal plates, sensors, and electronics components.

| Model | |

| Laser type | Continuous impulse |

| Laser wavelength | 1070nm |

| Max. laser power | 1000W |

| Range of adjustable power | 1-100% |

| Repeat frequency | 5-10KHz(adjustable) |

| Pulse width | Continuous light |

| Welding depth | ≤1.2mm |

| Repeat precision | ±0.01mm |

| Power stability | ±2% |

| Survice medium | Rare earth doped fiber |

| Length of fibe-optical | 10m(standard) |

| Beam quality | Single mode/multimode |

| Interface of fiber-optical | QBH |

| Operation system | PC working |

| Life of diode module | >100000hrs |

| Cooling style | Water cooling |

| Power consumption | 6KW |

| Electric connection | 220V±10%/50HZ/30A 380V±10%/50HZ/30A |

Feature

● The heat affected metallographic high power fiber laser welding machine features a limited region of which the required heat input and shape variation can be minimized.

● The most important advantage is efficiency and speed. Because of the non-touch welding function, battery use is minimized.

● The laser source can be put anywhere during operation for small and closely spaced parts welding.

● A large range of materials can be welded using this equipment, even thin or small inner diameter components.

● The equipment effectively avoids metlback or welding drawbacks caused by arc blowing or electrode wear.

● The machine does not require vacuum or x-ray protection.

● The depth-width ratio of piercing welding can reach 10:1.

● Using a switch device, you can transfer the laser source to multiple stations.

● Minimal polishing is required after welding.