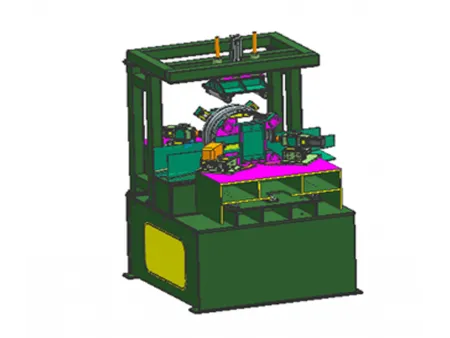

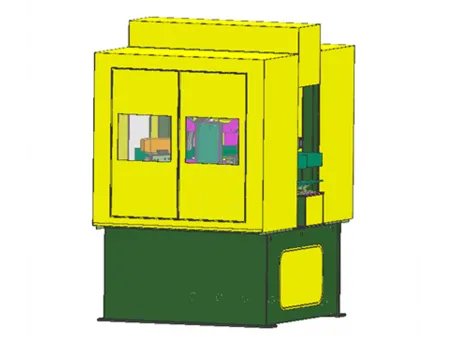

Rim Edge Deburring Machine

Request a Quote

The fully automatic edge deburring machine is a dedicated solution for rim edge deburring in wheel rim manufacturing. Designed for post-forming operations, the machine removes burrs from both rim flanges in a single pass, producing smooth edges with no visible burrs. The system consists of four main functional modules: a feeding unit, alignment unit, powered rim rotation unit, and powered deburring unit with grinding heads. With PLC-based control, the machine supports manual, semi-automatic, and fully automatic operating modes, ensuring flexible integration into different production lines.

Specifications

- Max. clamping force: 490kg (adjustable)

- Grinding feed pressure: 0-0.4MPa (precisely adjustable)

- Rotary servo motor power: 1.5kW

- Max. rim rotation speed: 40r/min

- Max. grinding head speed: 9000r/min

- Machine weight: approx. 4T

Processing StageProcessing Stage

- After roll forming

- Deburring

Features

- Machine frame: Fabricated from thick steel plates with welded construction. Post-weld stress-relief annealing ensures high rigidity, dimensional stability, and long-term precision.

- Four grinding heads configuration: Each side of the rim flange is equipped with two powered grinding heads, enabling high-efficiency, simultaneous deburring of both edges.

- Adjustable grinding angle: The grinding heads can be adjusted according to rim flange geometry within a range of 45° to 90° to suit different rim flange geometries.

- Diamond grinding wheels: The grinding heads are equipped with diamond abrasive wheels, offering long service life and stable grinding performance.

- Grinding control system: Utilizes Pneumatic damping control with constant-pressure grinding, ensuring stable contact force during deburring. Grinding pressure is precisely regulated via a precision pressure regulator.