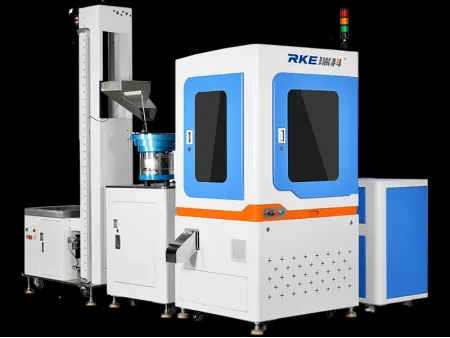

Integrated Inspection and Packaging Machine

The integrated inspection and packaging machine combines image recognition technology with automated packaging capabilities. It can be configured with a glass dial, indexing dial, or steel wire belt to provide comprehensive, high-speed inspection and packaging of products. It ensures precise detection and sorting, while concurrently handling packaging and counting tasks. This all-in-one solution is designed for low-cost, high-efficiency automated inspection and packaging operations, making it ideal for various industrial applications.

- Inspection speed: 200 pcs/min

- Inspection accuracy: ±0.01 mm

- Sealing ring

- Screw

- Screw

- Automotive fasteners

Inspection and Packaging Machine

- Applicable item size: 1-30 mm

- Inspection speed: 200pcs/min

- Sorting precision: 0.01mm

- Camera: industrial camera

- Air pressure: 7kg/cm²

- Voltage: 220V

- Rated power: 3000W

- Machine weight: 650kg

- Machine dimensions (L×W×H): 1350×1100×1800 mm

- Multiple widths

- Major and minor thread diameter, pitch, and angle

- Thread damage

- Presence or absence of threads

The integrated inspection and packaging machine consists of an automatic feeding system, transmission and positioning system, automatic measurement system, automatic sorting and unloading system, intelligent control system, and computer data processing system. These components work together to automatically measure the specified inspection items, sort products into qualified and unqualified categories based on their measurements, and perform statistical analysis and counting for packaging.

- The machine employs advanced AI deep learning software in combination with 15 color industrial cameras to perform high-precision inspections.

- Tailored to meet specific customer needs, the machine inspects 15 surfaces of the product for a variety of defects, including crushes, dents, and color differences.

- Equipped with an automated conveyor belt, the machine facilitates smooth product unloading. Products are collected in sets of 500 in a rotating collection box, ensuring efficient and organized processing.