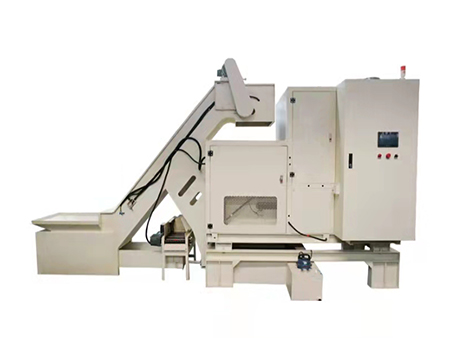

Briquetting Machine

The briquetting machine compresses the biomass within an environment of high temperature and pressure.

The machine has a large piston which carries out the task of grinding, compressing and extruding the biomass to for briquettes.

Liquid is squeezed off the solid particles during compression.

The biomass has a natural lignin content that serves as glue when liberated under high temperature and pressure.

This eliminates the need to use a binding agent during the whole process hence the end-product is a clean, green fuel that does not have harmful additives and is ideal for furnaces, boilers, open fires and other applications.

The briquetting machine is widely used in the mining industry for iron ore concentrates, steel slag, aluminum ash, Si-Mn mineral powder, chromate ore concentrates, etc.

As a briquetting machine manufacturer in China, Henan Hongji makes continual efforts to improve our technologies and upgrade various systems. We strive to provide the best briquetting machine as well as cement equipment, fertilizer equipment, mining machine, crushing equipment for our customers. Our products have received ISO9001:2000 certification and SGS certification.

At present, we have established a good cooperative relationship with many users in Vietnam, Bengal, Myanmar, Laos, Peru, Philippines, Iran, India and other countries. We sincerely hope that we can provide service for more users all over the world.

If you have any problem, please feel free to tell us.

| Model Type | ||||||

| Capacity | t/h | 4 | 6 | 10 | 15 | 20 |

| t/y | 10 000 | 20 000 | 30 000 | 50 000 | 70 000 | 10 000 |

| Roller Width | 250mm | 250mm | 336mm | 336mm | 400mm | 500mm |

| Roller Dia. | 360mm | 400mm | 500mm | 650mm | 750mm | 1000mm |

| Power | 7.5-15kw | 11-18.5kw | 18.5-22kw | 22-30kw | 30-55kw | 55-75kw |

| Axis Speed(r/min) | 18 | 15 | 13 | 13 | 13 | 13 |

| Reducer | ZQ350 | ZQ400 | ZQ500 | ZQ650 | ZQ750 | ZQ1000 |

| ZQ400 | ZQ500 | ZQ650 | ZQ750 | - | - | Strengthen |

| Pressure Form | Constant Pressure | Constant Pressure | Constant Pressure | Constant Pressure | Constant Pressure | Constant Pressure |

| Shell Frame | Shell Frame | Hydraulic/ Constant Pressure | Hydraulic/ Constant Pressure | Hydraulic/ Constant Pressure | Hydraulic/ Constant Pressure | - |

| Roller Material | 65mn | 65mn | 65mn | 65mn | 65mn | 65mn |

| - | - | 9cr2mn | 9cr2mn | 9cr2mn | 9cr2mn | Foundry |

| Structure | Two-Roll Single Pressure | Two-Roll Single Pressure | Two-Roll Single Pressure | Two-Roll Single Pressure | Two-Roll Single Pressure | Two-Roll Single Pressure |

| Four-Roll Double Pressure | Four-Roll Double Pressure | Four-Roll Double Pressure | Four-Roll Double Pressure | Four-Roll Double Pressure | Four-Roll Double Pressure | - |

| Axis Bearing | 319×4 | 319×4 | 2097724×4 | 2097724×4 | 2097724×4 | 2097724×4 |

| Principal Axis | 95mm | 110mm | 135mm | 165mm | 165mm | 250mm |

| 45#Steel | 45#Steel | Forge Piece | Forge Piece | Forge Piece | Forge Piece | - |

| Ball Size | Customization | Customization | Customization | Customization | Customi- zation | Customi- zation |