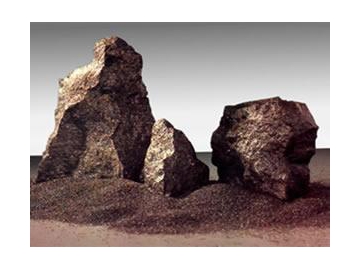

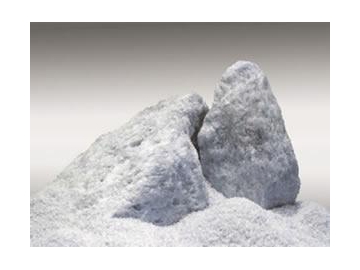

Brown Fused Alumina

Brown fused alumina is an abrasive media or refractory material produced from bauxite, anthracite coal and iron, each of which undergoes a fusing process together in an electric arc furnace. Located in Luoyng, we have a unique raw material supply in Yichuan’s large reserve of coal and bauxite.

Features of Brown Fused Alumina

1. This fused alumina features a high purity, breathability, thermal stability, toughness, refractoriness, high abrasion resistance and a high grinding ratio.

2. As an abrasive material, it can be made into abrasive tools to handle metals with a high tensile strength, including various steel, grinding wheels, and cutting tablets.

3. The brown fused aluminum oxide can also be used in industrial smelting process or the manufacturing of premium refractory materials.

Applications of Brown Fused Alumina

Corundum is a tough, hard material with a high strength, excellent wear and corrosion resistance. It is widely used as an abrasive material in the production of CRT, optical glass, crystal glass, jade and other products. As one of the most commonly used raw materials for abrasive manufacturers, brown corundum is applicable for polishing, grinding and other processes.

As the corundum has a high temperature resistance and thermal conductivity it can be turned into light weight corundum bricks, alumina hollow balls and fiber products. It can also be applied to walls and roofs of different high temperature furnaces. This tough and hard material can be used for the manufacturing of resin bonded abrasives according to particle sections and edge retention.

Specifications of Brown Fused Alumina

There are two types of brown fused alumina: abrasive and refractory:

Abrasive type: F12 - F220;

F12, F16, F20, F22, F24, F30, F36, F40, F46, F50, F60, F80, F100, F120, F150, F180, F220. Among these models, the F24, F30, F36 are best favored by customers.

Refractory type: 0-1MM, 1-3MM, 3-5MM, 5-8MM, 8-12MM, 100MESH, 200MESH, 325MESH. Here, the 0-1MM, 1-3MM, and 3-5MM are the most popular.

Processing

Smelting and deep processing are two major processes involving brown fused alumina.

1. Bauxite, iron and anthracite are blended into a specific ratio, and the mixture is then fed into a 2,200ºC electric arc furnace.

2. Brown fused alumina blocks will be manually selected and ground using a rolling mill or Barmac crusher. After magnetic separation, sieving, sampling and inspection, qualified fused alumina will be packed and stored in our warehouse.

Chemical Composition

Brown Fused Alumina 95% Min| AL2O3 | SiO2 | Fe2O3 | TiO2 | CaO | MgO |

| 95%min | 1.9%max | 0.5%max | 2.8%max | 0.6%max | 0.5%max |

| AL2O3 | SiO2 | Fe2O3 | TiO2 | CaO | MgO |

| 90%min | 3.5%max | 1.5%max | 4.5%max | 1.0%max | 0.8%max |

Note: we can also manufacture fused alumina upon your technical requirements.

Packaging

1. Ton Bags

2. 25kg bags and then 1000kg bags

3. Kraft bag

4. Tray

5. Custom