Roller Kiln

RollerKiln Pre-kiln centralized fumeexhaust zone Pre-heating transittemperature rising zone High temperature firingzone Rapid cooling zone Mild cooling zone

.jpg

The roller kiln generallayout is divided into several distinct segments. Each section varies in lengthdepending on the type, quality and volume of products that need to be fired.

1.jpg Roller kiln firing with coal gas

02.jpg~03.jpg Roller kiln firing with coal gas

2.jpg~5.jpg Natural gas roller kiln

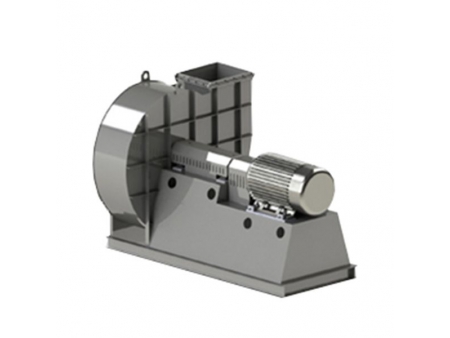

Features of Roller Kiln

1. Available in modular segments or pre-assembledin factory

2. Operates on fuels including LPG, naturalgas, coal gas, diesel, or heavy oil.

3. Advanced isojet burneroperates on an open-flame principle, having low flow capacities. PID controllerenables automatic temperature adjustment. An optimized kiln chamber designprovides a minimized temperature gradient across the kiln width. The operatingtemperature in the chamber could reach

4. High-grade refractory insulations, paired with a uniquely structured chamberwall, provide excellent insulating properties which minimizes fuel consumption.The outside kiln temperature is under

5. The top of the roller kiln can be built in different styles, drop ceiling,drop panel, and arch-shaped. This is done to prevent the top from shedding,reduce repair times, and to extend the life of the furnace.

6. Conveyor rollers are divided into sections, each section being individuallycontrolled to operate at different speeds. Rollers are driven by bevel gearswith a 45° pitch angle. Cycloidal speed reducer provides variable speeds for steady running.

7. Computer monitoring system digitalizes the preheating, firing and coolingprocesses.

| Title | Roller Kiln | Roller Hearth Kiln | Zhongyao |

| Keywords: roller kiln, roller hearth kiln, fast firing kiln | |

| Description | Zhongyao roller kiln is designed and built with advanced heating and temperature control technologies in it. |