Welding Glass

This product has been discontinued and removed from our shelves.

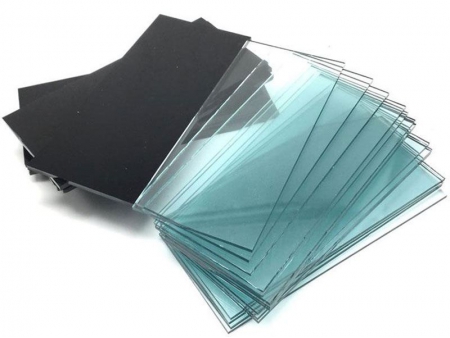

Color: clear, black, green

Thickness: 2 mm, 3 mm, and etc.

Sizes: 75*98 mm, 50*100 mm, 51*108 mm, 30*110 mm, 60*110 mm, 85*110 mm, 90*110 mm, 165*110 mm, 136*183 mm, 762*150 mm, 915*150 mm, or other custom sizes

Welding glass, also known as welding lens, protective lens or welding shield, is a vital component in welding helmets and laser safety glasses that protect welders from the dangers of intense visible light.

Welding is a process that uses heat and pressure to join metal together, but it can cause flash blindness without proper eye protection. To address that issue, welding glass is designed to effectively block infrared and ultraviolet rays, reduce the amount of visible light that enters the eyes, and protect workers’ vision. It allows welders to perform their tasks with clarity and safety.

The 2-mm-thick white glass used in welding masks serves as a protective barrier against flying debris during welding, while the black glass is the actual filter in the welding helmet for blocking out harmful radiation and bright light. White glass is affordable and easy to replace, playing an important role in protecting the black glass from sudden temperature changes. To install the glass, firstly, remove the spring inside the helmet; secondly, insert a clean white glass, followed by a clean black glass and another white glass. Finally, put the spring back in place.

CHINASTAR GLASS offers high-quality welding glass that meets industry standards for safety and durability. Our welding glass is perfect for professionals who demand reliable protection and clear visibility while working.

- The black glass lenses of the welding helmet are typically numbered between No. 7 and No. 13, among which the most commonly used are No. 8, No. 9, and No. 10. For general welding tasks, an No. 8 or No. 9 lens should suffice, but for specialized work environments that require more protection, lens of a higher number may be needed.

- The darkness of the lens should be chosen based on the welding current. The darker the lens, the better it filters light and is more suitable for high-current welding tasks. It is important to choose a lens that is as dark as possible while still allowing you to see the melting pool clearly, which will help protect your eyes from harmful exposure to ultraviolet and infrared light.