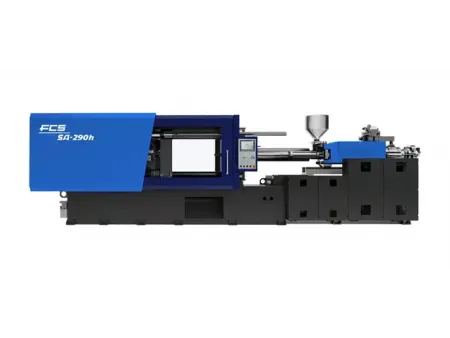

PET Blood Collection Tube Injection Molding Machine

Request a Quote

Description

220-290ton plastic injection molding machine for PET blood collection tubes

This injection molding equipment is designed to meet the high standards required for producing PET blood collection tubes, combining precise control with energy efficiency. Its capability to exert clamping forces from 220 to 290 tons ensures it can effectively handle demanding medical production needs.

Features

- Equipped with a highly rigid mold plate, this injection molding system ensures minimal deformation during operation, which is crucial for maintaining precise molding conditions

- The presence of a high-speed proportional valve accelerates the mold’s response times, enhancing both the opening and closing speeds which directly contribute to reduced cycle times and increased productivity

- A unique, welding-free construction in the piping system significantly reduces the risk of leaks, improving both the safety and the longevity of the equipment.

- Cleaner oil routes extend the lifespan of the molding machinery by preventing contaminant build-up that can lead to operational inefficiencies

- Integration with a KEBA control system simplifies the complexities of managing precision controls, making it easier for operators to achieve optimal results

- An ultra-fast action scanning cycle of less than 1ms ensures that every motion is executed with precision, critical for maintaining the high standards required in medical device production

- The layout of the equipment aligns with ergonomic principles, reducing operator fatigue and enhancing productivity during long production runs

- An infrared nano heating ring efficiently reaches and maintains the desired temperature, significantly reducing energy consumption by more than 30%

- Temperature fluctuations are tightly controlled within a ±1°C range thanks to a sophisticated PID temperature control system, ensuring consistent process conditions

- The plasticizing system benefits from a high L/D ratio screw that enhances the uniformity and quality of the molten PET, which is vital for producing high-quality tubes

- Dual linear guide rails on the injection platform minimize friction and enhance motion precision, further stabilizing the molding process

- Powered by a high-performance servo system, the equipment uses 30%-70% less energy compared to traditional systems, supporting sustainable manufacturing practices

- Modular design elements simplify the maintenance process, allowing quick access for repairs and adjustments which reduces downtime

- The molding equipment offers optional dual circuit actions, a feature that can drastically shorten the molding cycle times for facilities looking to maximize output

- With a medium inertia single-cylinder injection structure, the injection molding equipment starts quickly and maintains high repeatability, essential for consistent production of medical-grade tubes