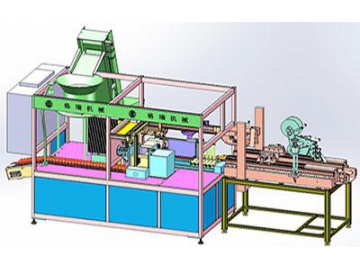

Big Bag Filling Packing Machine

Request a Quote

Application

The big bag filling packing machine has the function of feeding, weighing, bagging and dedusting. This machine is widely used in big bags of powder materials and FIBC bulk packing.

Applicable materials

Materials in the form of powder, such as cement, Iron powder, slag powder, fodder, carbon black, silica powder, feldspar powder, gypsum powder, zeolite powder and so on.

| Production capacity | 20-40 T/h |

| Weighing range | 1~1.5 T |

| Measuring accuracy | ≤±0.5% |

| Bag weight pass rate | ≥95% |

| Feeding mode | Double speed feeding |

| Control mode | PLC control |

| Total power | 5 KW |

| Air source pressure | 0.5 Mpa |

| Gas consumption | 0.6 m3/h |

| Dedusting air volume | 800-2500 m3/min |

| Environmental temperature | -10-40 ℃ |

| Overall dimensions | 3230*2180*4000 mm |

- High measuring accuracy: big bag filling packing machine is equipped with 0.02% high accuracy sensor which can control error within 0.5%.

- Stable feeding system: it adopts screw impeller with good sealing performance to control feeding, realizing intelligent control of feeding speed and improving the measurement accuracy greatly.

- Wide using range of packing bag: this machine can fill the packing bags ranging from 0.5 m³ to 2.0 m³which is suitable for almost all the big bags in the market.

- Convenient operation: the operations such as packing control, parameter setting and weighing calibration is easy and convenient.

- Easy extension: it is equipped with RS232, RS485 and other communication interfaces.

- Stable control: the packing machine adopts pneumatic control and it has simple structure and low noise, decreasing the mechanical vibration and trouble.

- Reliably sealing: the machine body is fully sealed and equipped with a dust removal port, which is durable and environmental friendly.

- Repair conveniently: the machine has reasonable structure design, which is equipped with maintenance platform, safety barrier and ladder stand.

- High level of automation: operations such as clamping, hanging, filling, weighing and unclamping can be finished automatically.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos