Intelligent Portion Cutter

Equipped with intelligent sensors and algorithmic control, the intelligent portion cutter ensures consistent thickness, weight, and shape for every piece of meat, improving presentation and ensuring even cooking. Its automated operation significantly reduces manual processing time, making it especially suitable for restaurant chains, food processing plants, and other high-volume meat handling environments.

Key Parameters

| Model | W300 |

| Conveyor belt width | 203.2 mm |

| Conveyor belt speed | ≤ 250 mm/s |

| Horizontal cutting size | ≥ 10 mm |

| Vertical cutting size | ≥ 6 mm |

| Input/output height | 1000 ± 50 mm |

| Power | 11.35 kW |

| Cutting temperature | ≥ -2°C |

| Power supply | 415 V, 50 Hz |

| Air pressure | 0.6 MPa (6 kgf/cm²) |

| Dimensions (L × W × H) | 2900 × 1750 × 1860 mm |

Features

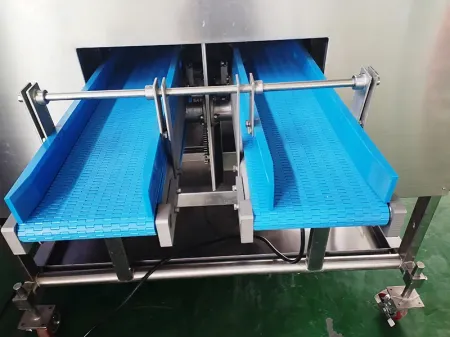

- Feed inlet

Wide feed inlet reduces the risk of blockage; conveyor uses food-grade materials for safety and reliability.

- Body and blades

Made mostly of food-grade stainless steel, resistant to corrosion and wear, easy to clean and disinfect, and hygienic for food processing.

- Automated portioning

This system eliminates the need for labor-intensive manual chopping. By placing meat into the feed inlet, the machine automatically portions it, significantly reducing labor costs and overall workload.