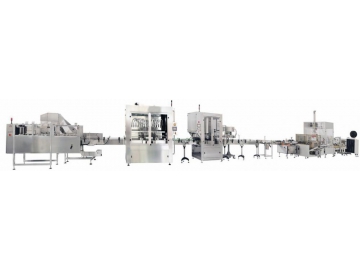

Oil Filling Machine

Method of Operation

The PET container is centered underneath the valve, and weighed using a load cell. Once the empty weight of the container has been calculated, the valve is opened, and the filling process begins. Two different speeds ensure the optimum flow for the oil filling machine. During the filling process, the load cell monitors the amount of the incoming liquid.

Once the pre-set weight is reached, the valve closes. After a short settling period, the weight is checked once more, and if it meets standards, the filled bottle leaves the small bottle filling machine.

1.Product tank2.Double-acting pneumatic cylinder

3.Valve stem

4.Neck-handling gripper

5.Weighing cell

Characteristics

High micro-biological safety through contact-free filling

Highly precise determination of the fill quantity using load cells

Perfect flow characteristics due to two possible filling speeds

Low-foam and low-turbulence filling thanks to flow rectifiers in the valve

Hygienic design

Electro-pneumatically controlled filling valve functions