C100-300/Z120-300 CZ Purlin Roll Forming Machine

Request a Quote

This purlin roll-forming machine can swiftly switch from a C-shaped to a Z-shaped profile in just 30 minutes. It produces purlin sizes ranging from 100 mm to 300 mm, with adjustments taking only five minutes. Additionally, our purlin machine can be equipped with a punch device for accurate hole punching, allowing easy screwing during installation.

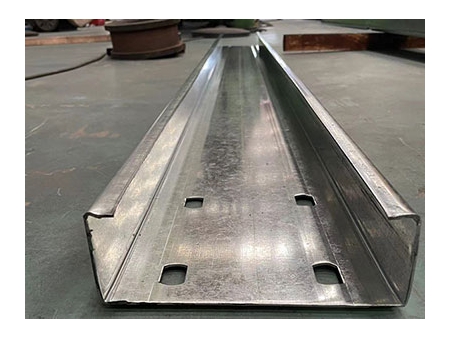

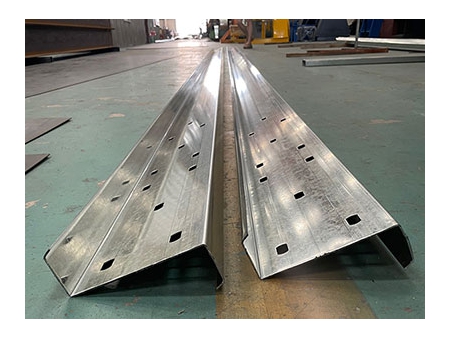

Samples

Profile Drawing

| Profile Model | Section | Thickness | ||

| Web | Flange | Lip | ||

| C100-300 | 100-300mm | 40-100mm | 10-20mm | 1.2-3.0mm |

| Z120-300 | 120-300mm | 40-100mm | 10-20mm | 1.2-3.0mm |

| Model | C100-300/Z120-300 |

| Dimension | 11000*1800*1500mm |

| Machine Weight | 11 tons |

| Size for C Purlin | 100-300mm |

| Size for Z Purlin | 120-300mm |

| Material Thickness | 1.2-3.0mm |

| Main Servo Motor Power | 30kW |

| Forming Steps | 23 steps |

| Running Speed | 0-30m/min |

| Hydraulic Power | 7.5kW |

| Machine Frame Material | H-Beam with 30mm thickness |

-

Roll Former

- Forming Steps: 23 steps

- Running Speed: 30m/min (without punching and cutting)

- Main Servo Motor Power: 30kW

- Roller Material: Gcr15/Cr12, CNC processing and heat treatment, hard chrome plated on the surface

- Shaft Material: 40Cr with shaft diameter of 90mm

- Machine Frame: 400# H-beam and A3 steel with 30mm thickness

-

Hydraulic Pre-cutting & Pre-punching Device

- Blade Material: Cr12Mov

- Surface treatment: CNC semi-finishing

- Vacuum treatment to 58-60HRC, CNC finishing

-

Hydraulic Post Cutter

- Cutting method: Multiple size cutting

- Blade Material: Cr12Mov

- Surface Treatment: CNC semi-finishing

- Vacuum treatment to 58-60HRC, CNC finishing

-

Hydraulic System

- Hydraulic Power: 7.5kW

- Hydraulic Brand: Yuken

- Oil Tank: 120L

- Cooling System: fan cooling

-

PLC Controller (Delta Brand)

- Punching position control

- Cutting position control

- Production batch quantity control

- Voltage: 380V/50Hz/3ph

- Steel Strip Uncoiler

- Roll Former Machine

- Hydraulic Pre-cutting Device

- Hydraulic Pre-punching Hole Device

- Hydraulic Post Cutter

- Hydraulic System (Yuken)

- PLC Controlling System (Delta Brand)

- Run Out Table