ERTi-1 (Titanium Grade 1) Titanium Welding Wire

Request a Quote

Welding Consumables

Commercially pure titanium filler metal for MIG and TIG welding in applications requiring ductility and resistance to high temperature and corrosion

- Standard: AWS A5.16

Chemical Composition (%)

| C | O | N | H | Fe |

| ≤0.03 | 0.03-0.10 | ≤0.012 | ≤0.005 | ≤0.08 |

Features

- Contains pure titanium, offering excellent mechanical properties with minimal impurities

- High strength and low density, making it suitable for applications requiring lightweight and strong materials

- Provides excellent corrosion resistance and toughness, ensuring long-lasting performance in challenging environments

- Easy to process and weld, making it a versatile choice for a wide range of industries

Applications

- Aerospace: Used for welding critical components such as aircraft frames, skins, and engine accessories

- Shipbuilding and marine engineering: Ideal for welding corrosion-resistant pipes, valves, pumps, and structural components in seawater desalination systems and other marine applications

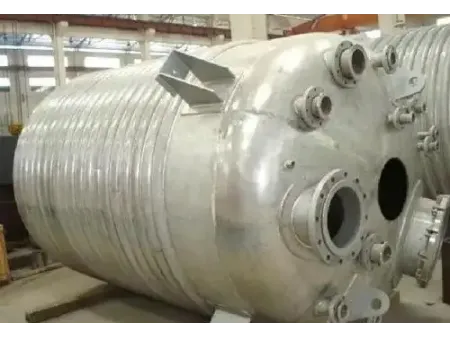

- Chemical industry: Used in welding heat exchangers, pumps, distillation columns, coolers, agitators, and other corrosion-resistant equipment

- Automotive industry: Applied in welding parts like diesel engine pistons, connecting rods, and leaf springs

- Medical devices: Welding of surgical instruments and other medical equipment

- Other applications: Used in heat exchangers for machinery, golf club heads, and metal 3D printing materials

Packaging

- MIG wire diameter (fine wire spooling): 0.8mm, 1.0mm, 1.2mm, 1.6mm

- Package: D300mm (10kg/spool), D100mm (0.8kg/spool)

- TIG wire diameter: 1.2mm, 1.6mm, 2.0mm, 2.4mm, 3.0mm, 4.0mm, 5.0mm, 6.0mm

- Package: 1000mm length (5kg/plastic box)

- TIG wire diameter (coil without spool): 1.2mm, 1.6mm, 2.0mm, 2.4mm, 3.0mm, 4.0mm, 5.0mm

- Coil inner diameter: D450mm, D300mm

- Package: 10kg/coil

Recommended Welding Method

- Tungsten inert gas welding (TIG welding)

TIG welding is a widely used method for titanium alloy welding. In this process, tungsten serves as the electrode, and argon is used as the shielding gas. The electric arc melts the joint between the titanium alloy plates to form the weld. TIG welding offers high-quality welds and aesthetic, smooth seams. - Metal inert gas welding (MIG welding)

Compared to TIG welding, MIG welding uses a consumable electrode (welding wire) and argon as the shielding gas. This method is ideal for welding thicker titanium alloy plates and provides higher welding efficiency. - Laser welding

Laser welding uses a high-energy beam to create deep, narrow welds, making it suitable for welding thin-walled materials. This method provides high-quality welds, high welding efficiency, and minimizes weld distortion.