MV/HV CCV Line for Medium Voltage & High Voltage Cables

110kV Cable Extrusion Line, Triple Extrusion

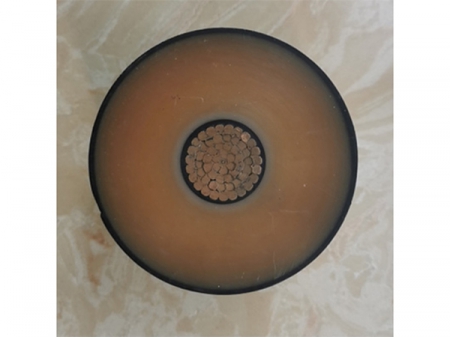

Baicheng 110kV cable extrusion line is a catenary continuous vulcanization line (CCV line) for production of high-grade XLPE insulated power cables up to 110kV. This cable production line carries out triple extrusion process of inner semiconductor layer, insulation layer and outer semiconductor layer in one pass. Our 110kV cable triple extrusion line mainly consists of extruders, crosshead, pay-off stand, accumulator, capstan, take-up stand, etc.

With the use of this CCV line, XLPE insulated power cables can be manufactured in diverse sizes, diameters, lengths, layer thickness and other technical specifications, and suitable for various applications including direct laying in the ground, burying in underground ducts, submerging under water and working on overhead transmission systems.

- Triple extrusion process for XLPE insulated cables of voltages up to 110kV;

- Capable of manufacturing power cables used for a variety of applications;

- Computer control, touch screen operation, Siemens TIA Portal software, and high-resolution HMI interface;

- Triple crosshead provides great convenience and ease of alignment;

- Customer-specific modified versions are available, which deviate from the standard version in speed adjustment by control of CV tube temperature;

| Voltage class | XLPE: 10-110kV | ||

| Conductor size | Cu: 25-1000mm2 Al: 35-1000mm2 | ||

| Max. cable weight | 14.5kg/m | ||

| Max. cable diameter | 80mm | ||

| Cable construction | Conductor screen (inner semiconductor layer) 0.5-2mm | Insulation 3.4-15mm | Insulation screen (outer semiconductor layer) 0.5-2mm |

| Line speed | 0-30m/min | ||

| Line execution | Half catenary | ||

| Length of cross-linking section | Approx.54m/9 sections (9 tubes) | ||

| Length of pre-cooling section | 12m/2 sections (2 tubes) | ||

| Length of cooling section | 84m/14 sections (14 tubes) | ||

| Arrangement of extruders | Φ80 extruder for conductor screen Φ175 extruder for cross-linked polyethylene (XIPE) Φ100 extruder for insulation screen | ||

| Electricity | Installation capacity 1000kVA | 380 V ±10% 60Hz±1% | 3 phase 4 wire |

| Water | Water pressure 0.2-0.6MPa | Water consumption 15m3/h (circulating water from reservoir) | |

| Compressed air | 0.6-0.8MPa | Air consumption 0.8m3/min | |

| Nitrogen | Pressure 2.0-2.5MPa | Purity 99.5% | Consumption 0.8-1m3/h |

| Nitrogen storage tank | More than 6m3×2 | ||

Extruder & Crosshead

Triple extrusion lines have three extruders connected to one common three-layer crosshead for the simultaneous extrusion of conductor screen layer, insulation layer and insulation screen layer.Control System

- Highly resistant to interference, minimum fluctuation of cables in tube, ensuring stable running and easy to maintain;

- Control system is placed at the middle part of heating zone, it can protect cables from contacting the tube wall during heating process;

- When the control receives the signal of cable position, the rotation speed of lower capstan (pulling) will be adjusted accordantly;

Pay-off Stand

Accumulator

Capstan

Accumulator & Upper Auxiliary Caterpillar

- Accumulator

- End Seal

- Extruder

- Lower Capstan

- Pay off Stand

- Upper Capstan