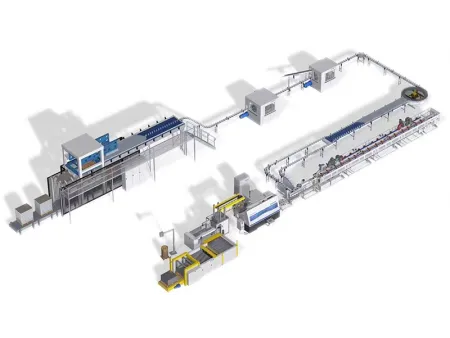

Can Depalletizer

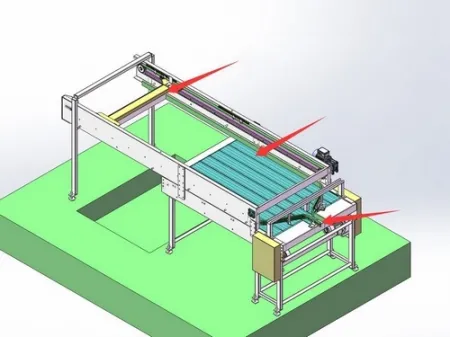

(Empty Can Depalletizer with Pusher)

The empty can destacker uses a pusher system to transfer empty cans from a fully loaded pallet to the conveyor, one layer at a time. Cans are moved off the pallet smoothly and steadily, then fed onto the production line for downstream processes such as cleaning and filling. This setup is well suited to empty can handling on modern tinplate can production and filling lines.

| Model series | |

| Stack height | 2400 mm |

| Suitable pallet size | 1100 × 1400 × 120 mm, suitable for wooden or plastic pallets |

| Destacker capacity | Typically 10–30 layers per minute (depending on product size and pallet pattern) |

| Suitable products | Tinplate cans, plastic bottles, glass bottles |

| Voltage & power | 3 × 380 V, 50 Hz, 7 kW (configured according to equipment power requirements) |

| Compressed air | 0.6 MPa, 0.1 L/min |

| Control system | PLC programmable controller, photoelectric switches, limit switches and pneumatic components from well-known German, Japanese and Taiwanese brands; pneumatic or electric drive, with optional servo system for high-precision movement |

Designed around a magnetic lifting mechanism, this empty can depalletizer combines a pallet lift with a conveying section to unload cans layer by layer from the pallet onto the conveyor. Magnetic holding force keeps tinplate cans stable during transfer, making it well suited for automatic depalletizing in can-making plants and for handling other ferrous products that require gentle, controlled unloading.

| Model series | |

| Stack height | 2400 mm |

| Suitable pallet size | 1100 × 1400 × 120 mm, suitable for wooden or plastic pallets |

| Depalletizing capacity | 300–1600 cans per minute |

| Suitable products | Tinplate cans, plastic bottles, glass bottles |

| Power supply | 3-phase 380 V |

| Compressed air | 0.6 MPa, 0.1 L/min |

| Control system | PLC programmable controller, photoelectric switches, limit switches and pneumatic components from well-known brands in Germany, Japan and Taiwan |