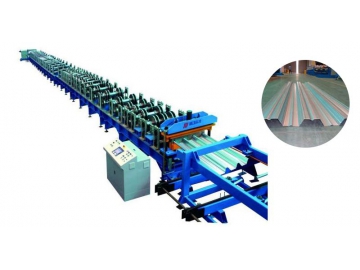

Roll Forming Machine (For Steel Sigma Profiles)

The roll forming machine supports efficient production of steel sigma profiles from cold rolled or galvanized steel strip.

Technical Data of the Roll Forming Machine| Suitable Material | Cold-rolled steel strip and heat-treated galvanized steel strip |

| Thickness of raw material | 1.0-3.0mm (235-345Mpa) |

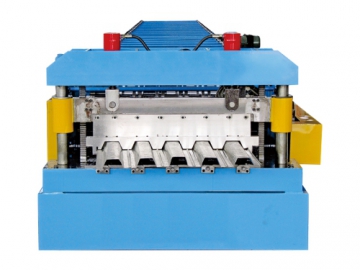

| Size of Sigma profile | 50-130mm adjustable (special size available) |

| Material of roller | Cr12 mould steel with quenched treatment, HRC58-60 |

| Material of cutter blade & punching die | Cr12 mould steel with quenched treatment, HRC58-60 |

| Material of shaft | High quality 45# steel with heat treatment. Roller grinder milling. |

| Forming speed | about 10-12m/min |

| Power requirement | Main motor power: 15 Kw(Depend on final design) |

| Hydraulic station power | 5.5Kw (Depend on final design) |

| Diameter of shaft for rollers | 82mm |

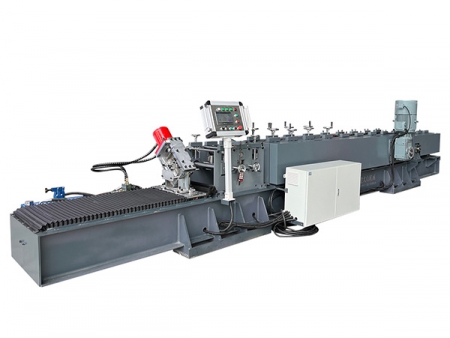

| Controlling system | Mitsubishi PLC & converter |

| Quantity of rollers | about 22 stations for main rollers |

| Weight of machine | About 10000KGS |

| Machine installation size | About 20mX2.5mx1.7m |

-

Roller is made of Cr12 mould steel with quench treatment. The hardness is about 60HRC. It is also plated with zinc for anti-rust treatment.

-

Your sigma machine can be designed here.

Advantages of the Roll Forming Machine

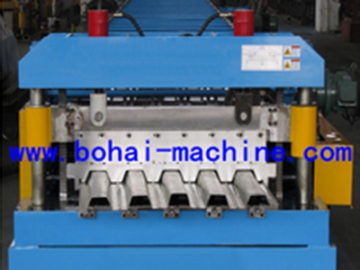

1. Anti-rust roller: The forming rollers for sheet metal fabrication equipment come with great anti-rust performance, as they are CNC machined and plated with 0.05mm thick hard chrome.

2. Heat treatment: The cutting frame undergoes special heat treatment to eliminate the steel stress, thus avoiding deformation.

3. Cutter blade: Made of Cr12 mould steel, the cutter blade for the roll forming machine also comes with quenched treatment, which ensures long service life.

4. High precision: The CNC processed forming rollers, coupled with precision ground roller shafts, provide the roll forming equipment with high performance precision.

5. User-friendly operation: Mitsubishi PLC control system with touch screen makes the sheet metal equipment easy for operation. User-friendly man-machine interaction.

6. Excellent services: We can send technicians to offer on-site roll forming machine installation and training services. Lifetime service is available for our metal forming machines.