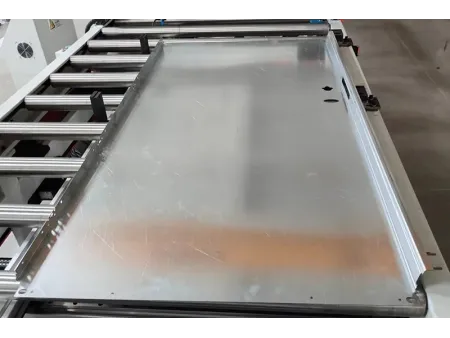

Steel Door Panel Roll Forming Machine

Request a Quote

NCM-560

Roll forming line for producing metal door leaves with roll stands at one side

NCM-560 door panel forming machine is suitable for roll forming the lock side/hinge side of the front and back panels of the door leaf. After one side of door panel is formed, roll forming of the other other side of door panel can be achieved by manually switching sides. It adopts fully automatic single mold roll forming method, which can be operated by a single person. The maximum forming speed of the machine for producing door panels can reach 12m/min. Additionally, sheet metal appearance can be added as needed.

Applications

- Security doors

- Fire-rated doors

- Healthcare/hospital doors

- Cleanroom doors

Technical Parameters

| Material thickness | 0.5-1.0mm,customizable |

| Material width | 400-1200mm,customizable |

| Production speed | 8-12m/min,adjustable |

| Power | 7.5-11kW,depending on product configuration |

Features

- Single forming stand with dual molds, capable of forming two different shapes at once.

- Roll-forming machine can achieve shapes that cannot be formed by bending/flanging.

Details

-

Machine Frame

The main frame is welded with square tubes, and the welded structure has undergone professional stress analysis.

The roll froming station is formed by cutting Q235 large plates at once, and then processed by CNC gantry milling.

A 20mm thick steel plate is added between the roll froming station and the lower machine frame to ensure the horizontality of the roll former. -

Roll Forming Machine

Utilizing a structure with a single forming stand and dual molds, it can simultaneously form two differetn shapes in one operation.

The roll forming molds are all processed using the CNC turning, heat treatment, CNC fine turing process, providing higher mold circularity and durability. -

Transmission Device

The roll forming station is equipped with a built-in transmission device, which prevents the dropping of debris and hand injuries.

The motor and reducer are placed inside the machine frame, saving operational space. -

Electrical Control System

The entire metal door forming machine is controlled by PLC system, optional in Delta/Siemens/ Mitsubishi, etc.